4085

Enhancing performance of a bio-inspired surface coil wtih a flexible metasurface for preclinical MRI at 7 T1Departamento de Fisica, UNAM, Mexico City, Mexico, 2Department of Physical Intelligence, Max Planck Institute for Intelligent Systems, Stuttgart, Germany, 3Electrical Engineering, UAM Iztapalapa, Mexico City, Mexico

Synopsis

Keywords: High-Field MRI, Non-Array RF Coils, Antennas & Waveguides, metamaterials

A bio-inspired surface coil was built for preclinical MRI applications at 7 T. Images were acquired with and without a flexible metasurface partially cover a cylindrical phantom. Images obtained with the metamaterial showed an important improvement of coil performance. No electronic components were used for tuning the metasurface. This easy-to-implement approach offers an alternative to improve the SNR for preclinical applications at high field.introduction

The coil geometry plays an important role in the MRI experiment to improve the sensitivity. A bio-inspired surface coil previously used for travelling-wave magnetic resonance imaging (twMRI), was used in this research because shows a high performance [1]. This coil configuration has also been numerically validated for MRI experiments at 15.2 T [2]. This motivated us to experimentally investigate the performance of this coil design using a metasurface [3] for preclinical MRI at 7 T.Method

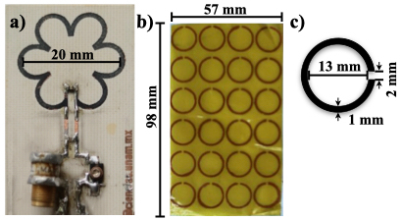

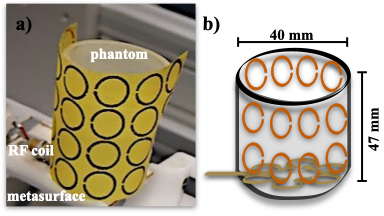

The surface coil proposed here is entirely based on the previous bio-inspired surface coil for twMRI [1]. A prototype of the bio-inspired surface coil was built, including six circular-type slots (0.45 cm dimeter) and total coil radius of 20 mm. The coil prototype was constructed using copper sheets laminated onto a nonconductive board (Fig. 1.a). Tuning and matching capacitors (0– 15 pF: Voltronics Co. Salisbury, MD, USA) were soldered directly onto the surface: two parallel ceramic capacitors (American Technical Ceramics, Huntington Station, NY, USA) were placed as shown in Fig. 1.a). The coil prototype was then matched and tuned to 50 Ω and 300 MHz, respectively (proton frequency for 7 T). The metasurface was formed by an array of 4 x 6 C- shape (Fig. 1.b) units and constructed using flexible hydrocarbon ceramic laminates (RO4003C3: 𝜖 = 3.55 and tan(𝛿) = 0.0027, thickness = 0.508 mm, 98 mm long and 57 mm wide). The C-shaped unit had a 13 mm diameter and a gap of 2 mm and a 1 mm strip width and were printed on this flexible material above, see Fig. 1.c). This metasurface is based on the cylinder of split-ring resonators reported by Vakili et. al. [4]. We obtained phantom images using a cylindrical phantom (40 mm diameter and 47 mm) filled with saline solution and the metasurface surface was wrapped around the phantom as shown in Fig. 2. Then, the bio-inspired surface coil placed under the cylindrical phantom and the metasurface was partially covering the phantom as shown in Fig. 2.b). To test the validity of the metasurface, phantom images were acquired using a standard gradient echo sequence. The acquisition parameters were: TE/TR = 4.39 ms/200 ms, FOV = 40 mm x 40 mm, matrix size = 256 x 256, Flip angle = 450, slice thickness= 2 mm, NEX = 1. Additionally, phantom images without the metasurface were also acquired for comparison purposes. All MRI experiments were performed on a 7T/30cm Bruker imager (Bruker, BioSpin MRI, GmbH, Germany).Results and Discussion

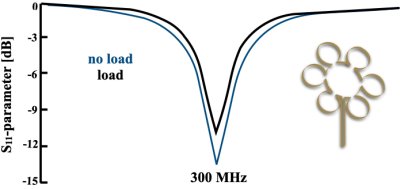

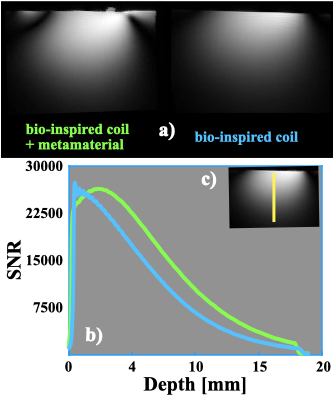

The return loss plot of the S11-parameter was obtained and shown in Fig. 3. The S11 profile is smooth and well defined reflecting a good tuning to the resonant frequency with a good RF penetration. The coil performance measured via the quality factor, Q, was approximately 25, whereas for the unloaded (free space) case was 37. Phantom axial images were acquired with our surface coil prototype and the saline-filled phantom and with and without the metasurface to demonstrate the feasibility to be operated at 300 MHz and compatibility with standard pulse sequences. Fig. 4.a) shows the phantom images acquired as mentioned above. Image data were used to compute the image signal-to-noise ratio (SNR) giving: Bio-coilno meta/Bio-coilmeta = 80.03/115.10. A SNR improvement of around 30% was obtained for the metasurface case. A roll-off comparison of the SNR versus depth was acquired experimentally from the phantom images and shown in Fig. 4.b). The bio-inspired coil with the metasurface shows a remarcable increase on SNR values compared to the SNR profile with no metasurafce for most part of the profile. These are rather surprising results since no electronic components were either use to tune the cells in the metasurface to the corresponding resonant frequency of 300 MHz and niether dielectric materials were added. Unlike other results published elsewhere, the metasurface proposed here partially covers the phantom volume used for the MRI experiments [5].Conclusions

Our experimental results demonstrate that using the bio-inspired surface coil and a metasurface partially covering the imaging phantom, an important SNR improvement can be achieved. This easy-to-implement approach offers an alternative to improve the SNR for preclinical applications at high field.Acknowledgements

This project received funding from the UAM Division of Basic Science and Engineering under the Special Program for Education and Research (DCBI-190-2022).References

1. Vazquez, F. et. al. O. (2021). Remote RF excitation for small-bore MR imager at 15.2 T. Journal of Magnetic Resonance, 323, 106896.

2. Solis, S. et. al. Bio-inspired surface coil for preclinical MRI at 15.2 T. ESMRMB Congress (2019) 32 (Suppl 1): S404.3. https://doi.org/10.1007/s10334-019-00756-0.

3. Wiltshire, M. C. K. (2007). Radio frequency (RF) metamaterials. Physica Status Solidi (b), 244(4), 1227-1236. https://doi.org/10.1002/pssb.200674511.

4. Vakili, I. et. al. (2014). Sum rules for parallel-plate waveguides: experimental results and theory. IEEE Transactions on Microwave Theory and Techniques, 62(11), 2574-2582. 10.1109/TMTT.2014.2354592.

5. Chen, H. et. al. (2020). Metamaterial-inspired radiofrequency (RF) shield with reduced specific absorption rate (SAR) and improved transmit efficiency for UHF MRI. IEEE Transactions on Biomedical Engineering, 68(4), 1178-1189. 10.1109/TBME.2020.3022884.

Figures