4079

Compact 16T MRI Magnet: Feasibility Study and Risk Reduction

Minfeng Xu1, Steve Buresh1, Anbo Wu1, Shike Huang1, and Thomas Foo1

1Global Research, General Electric, Niskayuna, NY, United States

1Global Research, General Electric, Niskayuna, NY, United States

Synopsis

Keywords: High-Field MRI, Magnets (B0), Superconducting Magnet; 16 T

An electromagnetic design of a 16.0 T MRI magnet using a combination of Nb3Sn and NbTi superconductors has been completed. It consists of a 9.0 T inner Nb3Sn solenoid and a set of outer NbTi coils that produces 7.0 T field, for a combined 16.0 T field. The design revealed very high hoop tensile and axial compressional stresses in the Nb3Sn coil. Alloy-reinforced high-strength Nb3Sn wires were selected for use in this project. For a magnet to operate in a persistent mode, superconducting joints between Nb3Sn wire segments need to be developed. Various joint configurations were attempted with some success.Introduction

The 11.7 T whole-body scanner 1 installed in France and the first high resolution images in a live primate showed impressive results. To further increase signal-to-noise ratio (SNR), a 16.0 T compact MRI is proposed. The system will focus on brain imaging, with more powerful gradients than in a whole-body system. The Iseult 11.7 T magnet is a NbTi-based magnet sub-cooled with 1.8 K superfluid helium to gain the current and field margin. Our proposed 16.0 T magnet uses Nb3Sn superconductor wire for the higher field inner coil, and NbTi superconductor wire for the outer lower field coils. Because of the higher field capability of Nb3Sn, the magnet can be operated at pool-boiling liquid helium temperatures at around 4.2 K, similar to that of clinical MRI magnets, making the cryogenic system easier to build. However, the use of Nb3Sn brings new challenges, owing to its brittleness, and because the process for building and handling it is not as developed as with NbTi. In high field regions, the internal stresses are high. Brittle Nb3Sn filaments can be easily damaged without a careful and thorough mechanical design. Conventional Nb3Sn wires made with bronze, internal tin, and restacked-rod processes can yield high current density, but they lack mechanical strength. Special high-strength Nb3Sn wires are needed for the ultra-high field magnet designs. For MRI magnets, persistent mode operation does not require a power supply for normal operations. The magnetic field temporal stability is guaranteed without any influence from power supply ripples. To achieve persistent mode operation, superconducting joints need to be developed so that the resistance values of the joints are sufficiently low to not cause noticeable current decay in the magnet, thus securing temporal field stability.Theory and Design

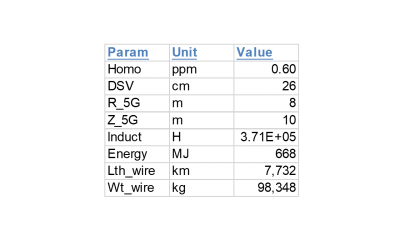

Electromagnetic (EM) studies, which involve selection and determination of conductor type, operating current, conductor dimension, image volume, homogeneity target on the image volume, and fringe field range containment, etc., are the foundation to any magnet. In our case, we chose a 26-cm diameter spherical volume (DSV) for the imaging volume, which is adequate for brain imaging. High homogeneity, <1 ppm peak-to-peak (p-p), at 26-cm DSV is desired to achieve high spatial resolution. The designed homogeneity was specified as 0.6 ppm to provide an adequate margin for finally shimming to <1 ppm. A fringe field (5 Gauss) line was specified to be the same as that for a 7.0 T clinical whole-body magnet (R = 8 m x Z = 10 m). A specially developed Nb3Sn wire by Furukawa Electric Co. (Tokyo, JAPAN) uses NbCu alloy surrounding Nb3Sn filaments to reinforce the wire, which strengthens the wire and shields the filament from excessive strain, protecting the wire from mechanical damage 2, 3. With this type of wire, we gained sufficient margin in mechanical strength, sacrificing some loss in current density, and subsequently the increasing the overall size and weight for the magnet. Experiments on developing superconducting joints are ongoing. Various configurations were considered: long filamentary, short and long scarf, and butt joints. Both unreacted wires and reacted wires were used, with better results from unreacted wires, which was expected.Results

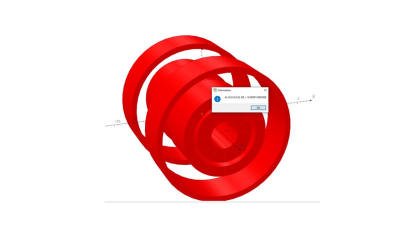

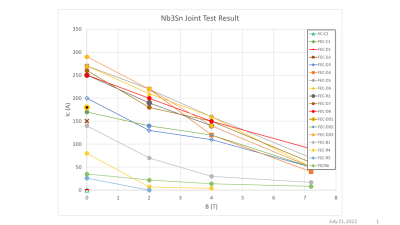

The main EM design values are listed in Table 1. In a 26-cm DSV, with the theoretical field homogeneity of 0.6 ppm p-p deemed as achievable. When the magnet is built, the actual homogeneity will deviate from the theoretical values, and will require shimming (a combination of active and passive shims) to reach <1 ppm at 26-cm DSV. The design achieved a fringe field range of R = 8 m, Z = 10 m, as in our initial specification. The stored energy in the magnet was 668 MJ. The estimated weight of the wires, both Nb3Sn and NbTi, was ~100 metric tons. The coil configuration is shown in Fig. 1, with one inner Nb3Sn solenoid, and five outer NbTi coils, including two bucking coils. The hoop tensile stress in the Nb3Sn solenoid was 76 MPa, and axial compressional stress was 31 MPa. Under such high stresses, conventional Nb3Sn wires would have little mechanical strength margin. With the Furukawa reinforced Nb3Sn wires, we have high confidence that the extreme high stresses can be sustained. The superconducting joint development results are shown in Fig. 3. Since the Nb3Sn joints are at the ends of the Nb3Sn solenoid, the joints need to work in a local magnetic field environment of 7.0—9.0 T. Our goal was to achieve 100 A at 7.0 T as a magnet coil current capability for the 16.0 T design. As this is a feasibility study, there are still several issues and risks to be addressed. We have focused on addressing the key risks but there remains more work to be done before a full-scale magnet can be built.Conclusion

An initial 16.0 T MRI magnet design using both Nb3Sn and NbTi wires was completed. NbCu-reinforced Nb3Sn wires were used to accommodate the expected high stresses. Superconducting Nb3Sn wire joint development is ongoing, with some encouraging results.Acknowledgements

This project was funded by NIH R01EB029814References

1. Quettier L, 2022 Applied Superconductivity Conference invited talk, 1LOr1A-02

2. Sugimoto M, Tsuboushi H, Engoh S, et. al, IEEE Trans on Appl. Supercond. 2016, 26, 8402205

3. Omura T, Oguro H, Awaji S, et. al, IEEE Trans Appl. Supercond. 2016, 26, 8402605

Figures

Fig. 1. Coil configuration of a 16 T MRI magnet EM design,

showing totally 6 coils. The inner-most coil is a Nb3Sn solenoid, generating 9

T field in the image volume. The radially outer coils are NbTi coils, producing

7 T in the image volume, for a combined 16 T.

Fig. 2. Superconducting joint test

results showing critical current versus applied magnetic field. Our goal is 100

A at 7 T. More development efforts are needed.

Table 1. Magnet key parameters

DOI: https://doi.org/10.58530/2023/4079