1056

A 32-Channel 3D-Printed-Loop Receive Array with Direct High-Impedance Preamplifiers for Brain Imaging at 7T1BAOBAB, Université Paris-Saclay/CEA/Joliot/NeuroSpin, GIF-SUR-YVETTE, France, 2Multiwave Imaging SAS, Marseille, France, Metropolitan, 3DACM, Université Paris-Saclay/CEA/IRFU, GIF-SUR-YVETTE, France, 4LCAP, CEA/DRF/IRFU/DIS, GIF-SUR-YVETTE, France

Synopsis

Keywords: RF Arrays & Systems, RF Arrays & Systems, Coil

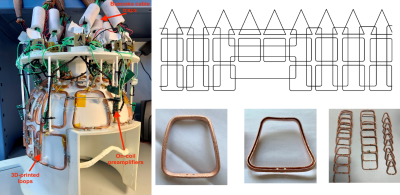

A fully customized 32-channel receive array has been designed, fabricated and evaluated using MR experiments at 7T. The design is made of non-geometrically decoupled loops arranged in two layers of large and small loops. Copper loops are 3D printed from additive manufacturing, preamplifiers are home-built, and an easy implementation procedure is proposed. Receive array performances shows SNR comparable to the Nova Medical reference coil while being superior at the top of the coil and for parallel imaging accelerated in the vertical direction.Introduction

Traditional implementation of receive arrays at 7T requires a complex iterative procedure while the use of low-impedance preamplifiers offers limited degree of freedom for decoupling optimisation. In addition, the reference Nova coil (Wilmington, MA) has a very narrow casing (18.5-cm wide in the left-right dimension), which prevents adequate ear protection or audio-stimulation for large heads. We propose a new coil design with increased dimensions and non-geometrically decoupled loops arranged in two layers with home-built preamplifiers directly placed on the loops. Moreover, to make full use of new Electron Beam Melting (EBM) additive manufacturing1-3 techniques, the 3D printing process of loops is investigated for reproducibility purposes.Methods

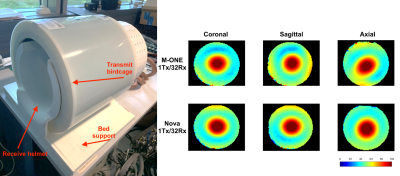

The helmet dimension is 20.5cm wide and 22cm high. For patient comfort and to enable convenient fMRI studies, a large opening is kept around the eyes, nose, and mouth. This receive array is integrated into a dedicated detunable transmit-only birdcage coil. The coil system will be next referred to as “M-ONE”, name of the associated EU-funded project.The inner layer is composed of 24 small loops in 3 rows with different sizes (Fig.1) and the outer layer is composed of 6 large loops and 2 supplementary loops around the eyes and forehead. The outer layer serves to fill the gaps between the small loops and to enhance sensitivity deeper in the brain. The loops within the same layer are non-overlapped in order to lower the g-factor4 and to facilitate implementation. The loops are 3D-printed in pure copper using the Electron Beam Melting (EBM) additive manufacturing technique. A “U” section is chosen to facilitate implementation and better mechanical strength. Preliminary tests demonstrated an SNR similar to that of a conventional copper wire. Each loop mounted on the helmet is tuned (reactance zeroed) at the Larmor frequency (1H at 297.2MHz) inside the detuned birdcage coil (all other loops are left open). A set of 32 preamplifiers was produced in-house, with SNR performances comparable to WanTcom’s WMM7RP (Chanhassen, MN): SNR variation was less than 1dB and preamplifier decoupling showed an average blocking impedance5 of 240 Ω presented to the coil ports. This in-house solution allowed to control trade-off between noise figure and preamplifier decoupling and cost half the price of the commercial preamplifier. The high-impedance technique facilitates the implementation as the preamplifiers were directly connected to the loops and no further iterative tuning was required.The SNR of the whole array was simulated and showed expected performances comparable to the Nova coil5.

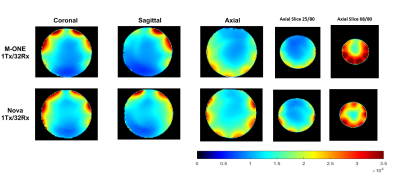

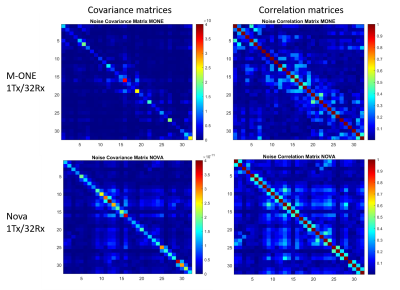

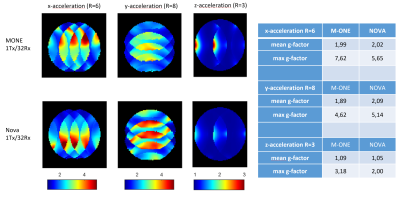

The experimental SNR is computed on a spherical agar phantom (16cm diameter with εr = 72; σ = 0.9 S/m; T1 = 577ms) centered in the helmet using GRE sequence (2mm isotropic resolution, TR = 10ms, TE = 3ms, FA = 8°, acquisition matrix = 128x96x80), and a 0V acquisition for noise measurement. Scanner data is pre-whitened and the image is reconstructed with a sum-of-square Rx-combination; SNR is corrected for excitation disparities. The g-maps are computed in post-processing with the SENSE algorithm6.

Results and Discussions

Flip angle maps are shown for both coils in Figure 2. Among multiple experiments with slight phantom positions changes, the SNR averaged on the whole phantom shows that the M-ONE coil achieves between 93% and 99% of the NOVA coil SNR (Fig.3). Nevertheless, the SNR distribution is different between the two coils: the top half of the sphere (along B0 direction) showed an improvement of 1 to 4% compared to the Nova while the bottom half had 85 to 90% of the NOVA coil’s SNR. The greater number of small elements compared to the reference at the top of the coil explains the higher SNR.The noise correlation matrix off-diagonal elements shows a mean value of 7.4% and a maximum 47.1% compared to 9.3% mean and 44.8% maximum for the Nova coil (Fig.4). The non-overlapping loops within the same layer are beneficial to reduce noise correlation7. The g-maps are computed for acceleration factors of 6, 8 and 3 in directions x, y, and z, respectively (Fig.5). While M-ONE coil shows higher g-factors when z-accelerated, lower g-factors are found when accelerating in the y-direction, and the same performance is observed in the x direction. The high number of channels of the M-ONE coil in the y-plane accounts for these lower g-maps compared to the reference, whereas the higher number of channels in the z-direction is beneficial for the Nova coil.

Conclusion

A fully customized 32-element receive array with increased dimensions was built using copper 3D printing technique, and low-cost home-built preamplifiers. Its performance demonstrated global SNR and g-maps comparable to the reference Nova coil while providing superior SNR at the top of the phantom and for parallel imaging accelerated in the y-direction. The 3D printing process associated with direct high-impedance preamplifier provides a fast and low-effort integration procedure to build high-channel-count receive array, whose SNR and g-factors can be easily shaped to best fulfil any specific application. Future developments will focus on increasing preamplifier decoupling performances as well as choosing a low-loss substrate for preamplifiers PCB. For the next step, in-vivo experiments will be performed, first in “restricted SAR” mode8 with the insertion of metamaterials9.Acknowledgements

These research activities have received funding from the European Union's Horizon 2020 research and innovation programme under grant agreement No 952106 (M-ONE project); from the Excellence Initiative of Aix-Marseille University – A*MIDEX, a French “Investissements d’Avenir” programme; and the Leducq Foundation (large equipment ERPT program, NEUROVASC7T project) for scanner acquisitions. Technological studies and the coil designs for additive manufacturing printing have been made as part of the CEA's ICARE skill transversal program, in collaboration with the teams from the DRF/IRFU/DIS and the DRT/LITEN/DTNM; loops were printed in collaboration with Aidimme (Valencia, Spain).References

1) H. Vanduffel et al. “Additive Manufacturing of Subject-Conformal Receive Coils for Magnetic Resonance Imaging” Advanced Materials Technologies n/a, no n/a (s. d.): 2200647. https://doi.org/10.1002/admt.202200647.

2) Guschlbauer, Ralf, Pär Arumskog, et Simon Eichler. « Electron Beam Melting of Pure Copper – From Research to Industrialization ». In 2020 IEEE 21st International Conference on Vacuum Electronics (IVEC), 89‑90, 2020https://doi.org/10.1109/IVEC45766.2020.9520506.

3) Luis Portolés Griñán et al. Pure Copper processed by Electron Beam Melting (EBM) technology for industrial applications - Euro PM2018

4) Larkman D.J. (2007) The g-Factor and Coil Design. In: Schoenberg S.O., Dietrich O., Reiser M.F. (eds) Parallel Imaging in Clinical MR Applications. https://doi.org/10.1007/978-3-540-68879-2_3

5) P-F Gapais et al. “SNR Evaluation with High Input Impedance Preamplifier Decoupling Performance for a 2-Layer and 32-Channel Receive Array for Brain Imaging at 7T” Proceedings of the ISMRM 2022 Conference, Abstract 1450

6) Pruessmann, Klaas P, Markus Weiger, Markus B Scheidegger, et Peter Boesiger. « SENSE: Sensitivity Encoding for Fast MRI », Magnetic Resonance in Medicine 42:952–962 (1999)

7) P-F Gapais et al. “On The Noise correlation in Receive Phased Arrays” Proceedings of the ISMRM 2022 Conference, Abstract 1537

8) N. Dudysheva et al. “New “restricted SAR mode” definition based on a thermal conservative model for relaxed unconditional safe in vivo experiments” Proceedings of the ISMRM 2022 Conference, Abstract 2550

9) Vergara Gomez, Tania S et al. “Hilbert Fractal Inspired Dipoles for Passive RF Shimming in Ultra-High Field MRI”. Photonics and Nanostructures - Fundamentals and Applications 48 (1 février 2022): 100988. https://doi.org/10.1016/j.photonics.2021.100988.

Figures

Figure 2: Receive array integrated with the transmit Birdcage (left) – Flip angle maps (in degrees) for proposed coil (top) and reference (bottom) with an agar spherical phantom.