3581

Magnetic Susceptibility of Common Metals and Alloys Used in Medical Devices1MED Institute Inc., West Lafayette, IN, United States

Synopsis

The goal of this study was to characterize the magnetic susceptibility and accompanying magnetically induced force, torque, and image artifact of metals and alloys that are commonly used in medical devices. These values were reported for 46 metals and alloys, with an overall trend that magnetically induced force, torque, and image artifact increased with increasing susceptibility of a material. The results of this study can inform medical device design for the development of safer and better performing devices, especially in the growing area of MR guided procedures.

Purpose

The magnetic susceptibility of a material largely contributes to how it interacts with the applied magnetic field of an MRI system. Consequently, magnetic susceptibility information can be used to inform medical device design for the development of safer and more effective devices that are used in MR environments. However, this information is often not readily available or is presented inconsistently. The purpose of this abstract is to characterize the magnetic susceptibility and accompanying magnetically induced force, torque, and image artifact of metals and alloys commonly used in medical devices.Methods

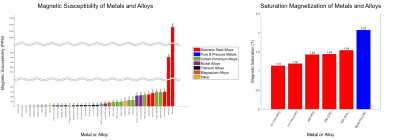

Forty-six metals and alloys that are commonly used in medical devices, supplied by Fort Wayne Metals (Fort Wayne, Indiana) in the shape of solid cylinders (i.e., rods). These rods were tested to determine their magnetic susceptibility and magnetically induced force, torque, and image artifact. The metals and alloys were categorized into seven broad groups: stainless steel alloys, pure and precious metals, cobalt chromium alloys, nickel alloys, titanium alloys, magnesium alloys, and other alloys. Dimensionless volumetric magnetic susceptibility of the metals and alloys was calculated using readings from an Evans balance (Sherwood Scientific Ltd., Cambridge, UK), shown in Figure 1 (a). This susceptibility was then converted to units of parts per million (PPM).The magnetically induced force of each of the metal or alloy rods was determined using the deflection angle test method (Figure 1 (b)) described in ASTM F2052 1. Saturation magnetization of each rod was then calculated through its relationship with magnetically induced force, which is outlined in ASTM F2052 1. The saturation magnetizations of six metals and alloys that had magnetic susceptibilities greater than what the Evans balance was capable of measuring were used for characterization in lieu of magnetic susceptibilities, which is common practice for ferromagnetic materials. The maximum possible magnetically induced torque for each of the rods was then calculated using saturation magnetization and magnetically induced force according to ASTM F2213 2.

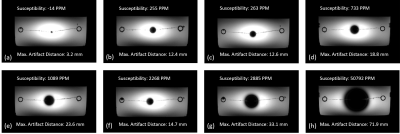

MR image artifact testing was performed using a gradient echo (GRE) pulse sequence with 100 ms repetition time (TR), 10 ms echo time (TE), 30° flip angle, and 5 mm slice thickness. The material with the highest measurable magnetic susceptibility from each of the seven material groups was tested for MR image artifact, plus one diamagnetic material (Au). Image artifact and artifact distance were determined and calculated according to ASTM F2119 3.

Results and Discussion

The magnetic susceptibility of the metals and alloys are shown in Figure 2 and Figure 3, along with the saturation magnetization of the metals and alloys that had susceptibilities above what could be calculated from Evans balance readings. For the materials tested, the stainless steel alloys group had the highest average measurable magnetic susceptibility (13298 PPM), followed by the cobalt chromium alloys (1533 PPM), the nickel alloys (1318 PPM), the other alloys (466 PPM), the magnesium alloys (279 PPM), the titanium alloys (194 PPM), and the pure and precious metals (57 PPM).Magnetically induced force and torque results are shown in Figure 3. Since some rod material samples had slightly different dimensions, the results shown were normalized to a uniform volume across all rods to replicate a medical device design process in which the device dimensions are fixed while the material selection is not. In general, the magnetically induced force and torque of the rods increased as the magnetic susceptibility of the rod material increased. MR image artifact results of the eight metals and alloys tested are shown in Figure 4. The results depict the worst-case image artifact of the rods in the axial orientation. Artifact distance increased with increasing magnetic susceptibility, with the exception of Inconel 625 (CW) (Figure 3(a)). However, the Inconel 625 (CW) sample had a significantly smaller diameter than the other samples, likely contributing to the smaller artifact distance due to the relationship between device size and image artifact distance 4. This knowledge of the relationship between magnetic susceptibility and image artifact size can be instrumental to the future design of devices to be used in MR-guided procedures.

Conclusions

Schenck (1996) untangled the ambiguous history of magnetic susceptibility and described the significant relationship between the magnetic susceptibility of a material and its interaction with an MRI system, highlighting the implications for device safety and performance 4. This research leveraged the principles of susceptibility explained by Schenck to characterize the magnetic susceptibility of metals and alloys commonly used in medical devices and their accompanying magnetically induced force, torque and image artifact. Future research will look to better define and quantify the relationship between magnetic susceptibility of a material and its magnetically induced force, torque, and image artifact.Acknowledgements

The authors would like to thank Fort Wayne Metals (Fort Wayne, Indiana) for supplying the metals and alloys tested in this study.References

1. ASTM F2052-15, Standard Test Method for Measurement of Magnetically Induced Displacement Force on Medical Devices in the Magnetic Resonance Environment, ASTM International, 2015.

2. ASTM F2213-17, Standard Test Method for Measurement of Magnetically Induced Torque on Medical Devices in the Magnetic Resonance Environment, ASTM International, 2017.

3. ASTM F2119-07, Standard Test Method for Evaluation of MR Image Artifacts from Passive Implants, ASTM International, 2007.

4. J. F. Schenck, "The role of magnetic susceptibility in magnetic resonance imaging: MRI magnetic compatibility of the first and second kinds," Medical Physics, vol. 23, no. 6, pp. 815-850, 1996.

Figures