0190

Additive manufacturing for the fabrication of subject-specific MRI passive shim and RF coil configurations

Hanne Vanduffel1, Cesar Parra1, Willy Gsell1, Rodrigo de Oliveira Silva1, Uwe Himmelreich1, Wim Vanduffel1, Dimitrios Sakellariou1, and Rob Ameloot1

1KULeuven, Leuven, Belgium

1KULeuven, Leuven, Belgium

Synopsis

Additive manufacturing methods are cost and time efficient methods, in particular, for the fabrication of subject-specific MRI hardware components. A novel powder-binder jetting method was developed to deposit variable concentrations of magnetic ink at precise pre-calculated positions to sculpt B0 towards a target distribution via the passive response of the 3D printed shims. Discrete spherical harmonic terms were printed as a proof-of-concept towards the manufacturing of subject-specific passive shims. Stereolithography (SLA) and Laser Powder Bed Fusion (L-PBF) manufacturing methods were developed for the fabrication of subject-specific RF coils. Significant gains in image quality, scan time and subject comfort were observed.

Introduction

Recent developments in additive manufacturing and data analytics have significantly advanced patient-specific medical devices in the healthcare sector. Additive manufacturing or 3D-printing techniques can be used to fabricate subject-specific MRI hardware components. Unlike conventional manufacturing techniques, additional geometric complexity in design does not translate into additional manufacturing costs or time. More importantly, the seamless transition between digital data and physical objects allows for integrating electromagnetic simulations prior to fabrication, facilitating design iterations.1 Patient-induced B0 inhomogeneities are an important factor significantly affecting the imaging quality in terms of signal-to-noise ratio (SNR) and geometric distortion.2,3 Since anatomical features are highly subject-specific, so are the type and extent of the magnetic field distortions. Traditional passive shims are constructed by placing ferro-, dia- or paramagnetic materials at discrete locations inside the magnet bore in an iterative process.2,4 This time-consuming process has difficulties rendering the higher-order spherical harmonics (SHs) terms required to shim field inhomogeneities induced by complex anatomical features. We developed a powder-binder jetting technique to manufacture subject-specific passive shims. The method deposits variable concentrations of magnetic ink at precise pre-calculated positions in a patient-specific shim design to sculpt B0 towards a target distribution via the passive response of the 3DP shims to B0. Shim designs producing discrete SH terms were fabricated as a proof-of-concept towards subject-specific passive shims. A poor geometrical fit between the RF coil and subject also limits SNR.5 Several approaches relying on flexible coil substrates have shown promising results.6–9 However, the flexibility hinders the precise and reproducible coil placement on the subject. We developed three additive manufacturing techniques for the fabrication of patient-specific RF coils. Proof-of-concept 3D-printed subject-conform coils were fabricated to image a human thumb's metacarpophalangeal (MCP) joint, demonstrating the feasibility and advantages of 3D printed subject-specific RF coils in a clinical setting.Methods

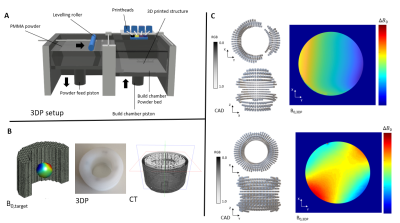

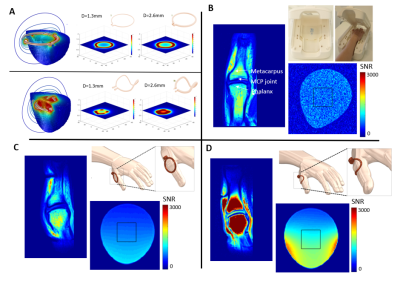

(i) 3D printed passive shims: Each ROI voxel of the phantom is assigned an error value (E=B0,i,initial - B0,i,target). A linear programming algorithm uses this spatial map of values to calculate which distribution and concentration of ferromagnetic ink are required in the shim volume to achieve the target B0 distribution. Both software and hardware (fig. 1A) were developed to enable complete control over (ketone-based) binder and magnetic ink composition and volume in every voxel of the printed (PMMA) object. X-ray CT was used to visualize the magnetic modifier distribution in the 3D printed object (fig. 1B). B0 maps of CuSO4 phantoms were acquired using a 9.4T pre-clinical scanner (Bruker). (ii) 3D printed subject conform RF coils: An automated digital design workflow was developed in Python for the geometric CAD modeling of RF coils based on subject-specific input data (Python, Rhino 7). These designs were used as direct input for EM simulations (COMSOL Multiphysics) (fig. 2A). RX coils were fabricated by direct liquid metal injection of 3D printed coil template channels. The performance of these coils was compared to reference standards (16 array commercial hand/wrist coil and molded Cu wire). MRI data of CuSO4 phantoms and the MCP joint of a volunteer were acquired (3T, Siemens). SNR maps were calculated for images formed from cov-rSoS and T1-weighted turbo spin-echo images (T1_TSE) (matrix: 384x384, TR=960, TE=15 , α=150, slice=3.3 mm, 20 images).Results

(i) 3D prints containing magnetic functionalized ink to produce 0th, 1st, and 2nd order SHs were successfully printed (xyz resolution = 300 µm) (fig. 1B). The response of the 3DP shim configurations to a B0 field of 9.4 T was analyzed using B0 maps (fig 1C). The 1st and 2nd order SHs were clearly visible in the respective B0 maps. (ii) A phantom fitting the subject-specific thumb coil (fig. 2D) was used to quantitatively analyze the performance improvement over a commercial 16 channel volume hand/wrist coil and non-conformal Cu surface coil (fig. 2B and 2C). SNR gains of 35% for the subject-specific liquid-metal-injected coil were obtained. The non-conform copper wire coil showed a decrease of SNR of 16% compared to the 16 channel array. In vivo SNR of the thumb MCP was obtained for a subject-conform single loop Rx coil and compared to a state-of-the-art 16-channel hand/wrist array, demonstrating the feasibility of the proposed 3D printing techniques in a clinical setting. A significant increase in SNR was obtained as a result of the improved filling factor of the subject-conform coils. Ligaments and cartilage were more clearly visible compared to the reference coils.Conclusion

The developed binder jetting 3D printing system and software technique was used to print functionalized 3D prints that induce 0th, 1st successfully, and 2nd order SH terms in B0. The results show that the proposed workflow can be used to sculpt the magnetic field distribution towards a more uniform state via the passive response of the 3DP shims to the primary B0 field. Significant SNR gains (up to 35% compared to state-of-the-art Rx coils) and enhanced spatial resolution obtained from the 3D printed subject-conform coils were achieved during the imaging of the MCP joint. These results demonstrate that 3D printed RF coils can diagnose imaging regions where standard coils don't suffice. These results demonstrate how 3D printing can be exploited as a time- and cost-efficient manufacturing method for the fabrication of subject-specific MRI hardware components.Acknowledgements

The authors acknowledge the financial support from KU Leuven (Project No. C3/21/027 and Project No. IDN/20/016), the Research Foundation Flanders—FWO Vlaanderen (SB Scholarship No. 1SB8519N), and the European Innovation Council (Horizon 2020: GAMMA-MRI 964644, EIC Women Leadership program).References

- Parra-Cabrera, C., Achille, C., Kuhn, S. & Ameloot, R. 3D printing in chemical engineering and catalytic technology: Structured catalysts, mixers and reactors. Chem. Soc. Rev. 47, 209–230 (2018).

- Wachowicz, K. Evaluation of active and passive shimming in magnetic resonance imaging. Res. Reports Nucl. Med. 1 (2014) doi:10.2147/rrnm.s46526.

- Stockmann, J. P. & Wald, L. L. NeuroImage In vivo B 0 fi eld shimming methods for MRI at 7 T. Neuroimage 168, 71–87 (2018).

- Yang, S., Kim, H., Ghim, M., Lee, B. & Kim, D. Local in vivo shimming using adaptive passive shim positioning ☆. Magn. Reson. Imaging 29, 401–407 (2011).

- Gruber, B., Froeling, M., Leiner, T. & Klomp, D. W. J. RF coils: A practical guide for nonphysicists. J. Magn. Reson. Imaging 48, 590–604 (2018).

- Nordmeyer-Massner, J. A., De Zanche, N. & Pruessmann, K. P. Stretchable coil arrays: Application to knee imaging under varying flexion angles. Magn. Reson. Med. 67, 872–879 (2012).

- Malko, J. A., McClees, E. C., Braun, I. F., Davis, P. C. & Hoffman, J. C. A flexible mercury-filled surface coil for MR imaging. Am. J. Neuroradiol. 7, 246–247 (1986).

- Adriany, G. et al. A geometrically adjustable 16-channel transmit/receive transmission line array for improved RF efficiency and parallel imaging performance at 7 Tesla. Magn. Reson. Med. 59, 590–597 (2008).

- Corea, J. R. et al. Screen-printed flexible MRI receive coils. Nat. Commun. 7, 1–8 (2016).

Figures

(A) Powder-binder jetting printer (B) (Left to right:) Target B0 distribution with surrounding shim voxels; 3DP passive shim; CT reconstruction of 3D-printed ferromagnetic distribution inside 3DP shim (C) Ferromagnetic distribution and B0 map of 1st order SH (top) and 2nd order SH (bottom)

(A) EM simulations of non-conform (top) and subject-conform (bottom) RF coil; (B) SNR map of MCP joint and phantom with commercial 16 channel hand/wrist coil; (C) SNR map of MCP of thumb and phantom with non-conform Cu single loop RF coil; (D) SNR map of MCP of thumb and phantom with subject-conform liquid-metal-injection single loop 3D-printed RF coil

DOI: https://doi.org/10.58530/2022/0190