4154

Material investigation for in vitro aneurysm flow model that mimics the arterial vessel and examining the flow in rigid wall model using 4D Flow MRI1Department for Radiology and Neuroradiology, University Hospital Schleswig-Holstein, Campus Kiel, Germany, Kiel, Germany, 2Institute for Materials Science, Faculty of Engineering, University of Kiel, Germany., Kiel, Germany, 3Section Biomedical Imaging, Molecular Imaging North Competence Center (MOIN CC), Kiel, Germany

Synopsis

Blood flow , which is one of the factors leading to aneurysm rupture, can be measured in vivo by 4D flow MRI. In this study, the flow in 3D printed, patient-derived models was measured in vitro. Elastic modulus of materials were investigated to mimic the real brain arteries.

Introduction

A cerebral aneurysm is a severe disease that leads to death in about 50 % of all cases if a rupture occurs [1] and need to be identified and treated. Blood flow is the one of the most critical factors leading to aneurysm rupture [2]. It can be detected in vivo using 4D flow MRI, but there is no clear understanding yet which of the parameters such as flow rate, pressure and wall shear stress are decisive. 3D models of aneurysms allow to tests treatment strategies in vitro. The emerging technique of 3D printing allows to produce patient derived models. The most commonly used printing materials, however, are rigid and don’t mimic the elastic properties of the vessel wall well. Thus our first goal is to measure flow rate in aneurysm model with a rigid wall using 4D Flow MRI. Our second goal is to determine the material that can mimic the brain arteries in order to examine the effect of vascular wall elasticity on flow.Materials and Methods

We investigated three kinds of commercially available material with different shore and elasticity values claimed by the manufacturer as 'Rigid' (Clear 78D material-1), 'Flexible' (material-2), and 'Elastic' (material-3,) photoreactive resins (Formlabs, USA).Determination of elastic modulus

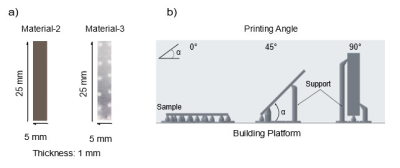

Samples

Rectangular samples of material-2 (“flexible 80A resin”, Formlabs, USA) and -3 (“elastic 50A resin) were designed and printed with stereolitography (Fig. 1); Autodesk Inventor 2021, Autodesk Inc., USA; Formlabs 3, Formlabs, USA) [3,4]. Because stereolitographic models are printed layer-by-layer, the resolution differs between layers. To investigate this effect, we printed the samples at printing angle a = 0°, 45° and 90° with respect to the printing platform (or printing layer). Three samples were printed for each material and printing angle (18 in total).

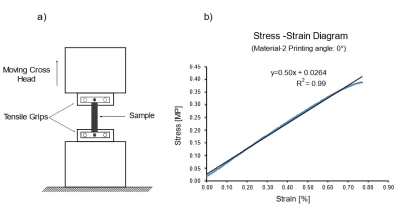

Tensile test

Tensile tests were performed in test machine (Zwick Roell Z05, Fürstenfeld, Austria) at 24 °C. The samples were and pulled until break (Fig. 2a). The force was measured as function of the disposition/strain and fitted with a linear function y=m x a +b., where m is the elastic modulus (Fig. 2b).

Flow measurements

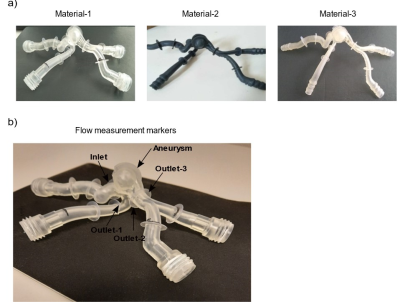

Patient-derived models of vasculature

3D image of flow model were obtained by in vivo from a patient with aneurysm and data was processed, then used for 3D printing with material-1,-2 and -3 (Formlabs 3, Formlabs, USA). The models were printed with three kinds of materials with different mechanical properties claimed by the manufacturer as 'Rigid', 'Flexible' and 'Elastic' photoreactive resins (Fig. 3). Rigid model was referred ad material-1.

Experimental flow setup

The flow models were placed in agarose gel and integrated in a flow loop filled with a glycerol-water mixute (40/60 %) with 0.3 mmol/L gadolinium-based contrast agent (Gadovist, Bayer Pharma AG, Germany) to mimic the blood. The models were supplied with a pulsatile (cardiac) pump (5000 Hz PD-1100, BDC Laboratories, USA) and flow rate was 300 ml/min at 24 °C.

4D flow MRI

Flow measurements were performed on a 3 T clinical whole-body MRI (Ingenia CX, 5.6.1, Philips Healthcare, Netherlands) using a spoiled, T1-weighted turbo fast gradient echo sequence (TR/TE = 8.5/5.1 ms, matrix: 528×528×80, voxel size: 1.5 mm³, field of view: 200.1×200.1 mm², number of heart phases: 20, temporal resolution: 50 ms, velocity encoding parameter: 70 cm/s, number of slices: 133). The flow was measured at the markers on the model. Flow was analysed with dedicated software (GT Flow, 3.2.13, GyroTools, Switzerland). The magnitude and phase difference images of 4D flow MRI were reconstructed on the MRI console.

Results

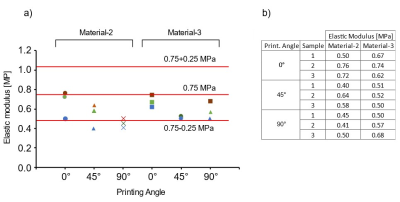

Tensile testElastic moduluses of 18 samples were obtained from tensile test. Values of 12 samples were changing between 0.75 ± 0.29 MPa which is the value of real artery in literature [5] as shown in Fig. 4.

4D Flow MRI

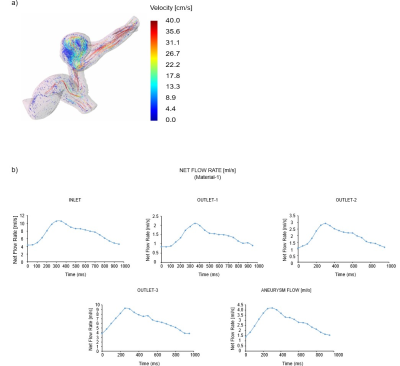

Flow was measured in model with material-1 has shown in Fig. 5a and net flow rates at the markers were obtained in aneurysm models using 4D flow MRI (Fig. 5b).

Discussion

Results in tensile test showed that the printing angle was effective on elastic modulus.The closest samples to 0.75 MPa were those produced at an angle of 0°/material-2 and /material-3. As shown in Fig. 4, samples were in the safety zone except the material-2 at 45° and 90°. As a result of 4D Flow MRI measurement of rigid model, average of net flow rates were in inlet and outlets 7.35, 1.38, 1.92 and 6.9 ml/s and 2.79 ml/s in aneurysm. Flow results obtained from the rigid model will be the reference. Thus, a realistic flow distribution will be obtained taking into account the wall displacement caused by pulsatile flow.Conclusions

We found two commercial resins which allowed to produce the flow models with elastic properties close to the human vessel. The combination of a more realistic model and 4D Flow MRI can facilitate the understanding of aneurysmal flow formation after the treatment.Acknowledgements

We are grateful for the financial and intellectual support by the Research Training Group "Materials4Brain" (GRK2154; P2b, P2a)References

1. Brain Aneurysm Statistcs and Facts. Brain Aneurysm Foundation. https://www.bafound.org.

2. Sforza D. M. et. al. Hemodynamics of Cerebral Aneurysms, Annual Review of Fluid Mechanics Volume 41, 90-107 (2009).

3. Flexible 80 A Resin Data Sheet. https://www.formlabs.com

4. Elastic 50 A Resin Data Sheet. https://www.formlabs.com

5. Kamdaeng, T. et. al. Arterial stiffness identification of the human carotid artery using the stress-strain relationship in vivo, UltraSonics Volume 52/3, 402-411 (2012).

Figures