3346

En Route to multiphasic anthropomorphic MR phantoms: An additive manufacturing approach applying silicone 3D-printing techniques1Physikalisch-Technische Bundesanstalt (PTB), Berlin, Germany

Synopsis

Stable and well characterized anthropomorphic MR-phantoms for quantitative MRI of T1 and T2 measurements are still lacking. We investigate the potential application of additive manufacturing of silicone to produce multi-compartment MR-phantoms with well characterized relaxation properties. Various two-component silicone types with different mixture ratios were investigated. Additionally, the influence of admixing colors to modulate relaxation times was studied. First bi-phasic test samples were designed, produced by different commercial 3D printing sources, and characterized.

Purpose

Phantoms are of paramount importance for quantitative MRI and, so far, phantom work has predominantly been targeting T1 and T2 relaxation times. Here, we aim for a new approach to produce silicone-based, brain phantoms [1] utilizing the recent development of soft-matter additive manufacturing [2]. The technique is already capable of multi-component production [3], i.e. different ‘tissue-types’ can be intricately printed without the need for containers or walls for separating the compartments. This approach could open the path to anthropomorphic phantoms which not only will keep their MR characteristics over years but also could be produced ‘on-demand’.Methods

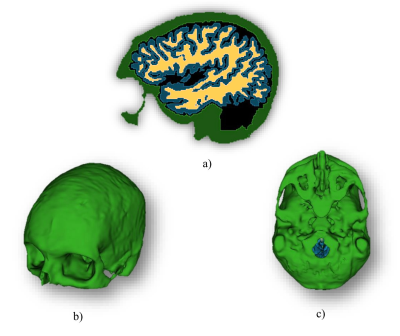

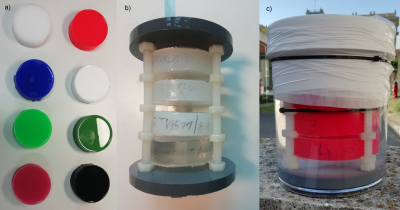

To implementing additive manufacturing to phantom production, suitable 3D models have to be generated fulfilling the process requirements. Most relevant is the minimal structure size such systems can realize. A workflow was developed utilizing the open source packages FreeSurfer, FreeView, SPM and 3DSlicer [4]. Thus, we were able to choose minimal gray matter thickness and eliminate any structures smaller than that (Fig. 1). Aside from the silicone approach shown here, this data-set was also used for other phantom production strategies [5,6].Silicone is widely applied and exists in numerous types. Up to now we have characterized room temperature vulcanization (RTV) two-component silicone from two different suppliers (Elkem, Germany: RTV4511, RTV4530, ESA6018; Silikonfabrik, Germany: SF00, SF13, SF33, Silixon10, Silglas10) with the recommended 1:1 mixture ratio but also with off-label ratios as far as 1:2. Various color pastes were test for further relaxation time adjustment. After vacuum degassing, the silicone was filled in molds of approx. 6.5 cm diameter up to a height of 1.5 cm (Fig. 2 a). For material characterization, four such discs were stacked with equal spacing (Fig. 2 b) and placed within a container filled with silicone oil (Fig. 2 c). This assembly was imaged (4 to 7 mm slice thickness, 0.9 x 0.9 mm² in-plane resolution, 10 s TR) in a 3T scanner (Siemens Verio) using an inversion recovery spin-echo sequence (25 – 6400 ms TI) for T1 analysis and a spin-echo sequence (12 – 10000 ms TE) for T2 analysis . Analysis was done offline applying single- or dual-exponential decay fits to the magnitude images pixel-by-pixel for T2 analysis whereas the complex data were used for T1 determination by fitting the signal sequence to the function A+B*exp(-TI/T1) with A and B being complex numbers [7].

Results

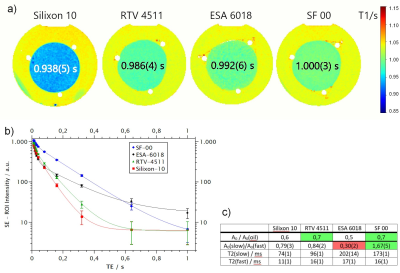

As a general result, we observe a decreasing MR signal with increasing hardness of the cured silicone type. Consequently, only the softest variant of the specific type was further investigated. Compared to the surrounding silicone oil, these soft silicone discs exhibit relative signal intensities of 50% to 80 % (Fig. 3c).For the softer silicone discs produced we observe T1 ≈ 0.9 - 1 s (Fig. 3a). Fitting the TE dependence of the spin-echo images with a single exponential decay results in residuals with still significant structure. Double-exponential fits eliminates this but do not easily converge for the pixel-by-pixel analysis. After ROI averaging within each TE-image the double-exponential fits converged well and all silicone types tested show a fast T2-component in the range of 10 – 20 ms and a slower component in the range of 70 – 300 ms (Fig. 3b, c).

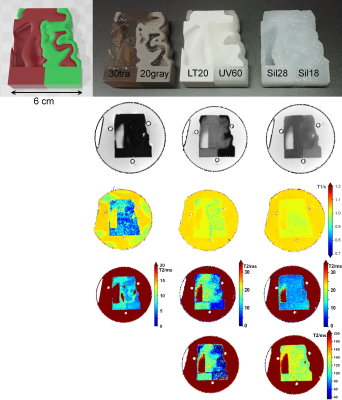

Apart from those mono-phasic discs, biphasic silicone samples were produced by commercial 3D-printing. A segment from the brain dataset with two homogeneous cubes added (Fig. 4 top left) was produced by the three companies with unaltered silicone types they routinely work with (Fig. 4 top row, ACEO, EnvisionTEC, SanDraw [3]) and measured in the scanner as described above. Apart from the ACEO sample we again see the difference in signal intensity depending on the silicone hardness. Almost no difference in T1 is seen between the silicone used by EnvisionTec and SanDraw. Their silicone also show the fast and the slow relaxing component in the T2 measurements.

Discussion and Outlook

Soft silicone types can be used for T1 phantoms and relaxation times comparable to the human brain can be obtained by choosing the appropriate base material. Further shortening of the T1 time could be achieved by adding graphite [1] or SPIOs. T2 relaxation turned out to be more complex as all tested silicone types show a fast and a slowly relaxing component. However, double-exponential T2 relaxation has been seen in tissue as well and T2 measurements are notoriously sensitive to experimental details [8]. Thus, one would determine an effective T2 time, when applying a mono-exponential decay fit, strongly dependent on the implemented echo times. As strong differences in the amplitude ratio of the two components have been found, a silicone mainly exhibiting the slow relaxation component may be found in not yet tested types. The application of adapted silicone to commercial 3D-printing technology shows potential for future production of on-demand 3D-printed MR phantoms.Acknowledgements

This project (QUIERO, grant number 18HLT05, quiero-project.eu) has received funding from the EMPIR programme co-financed by the Participating States and from the European Union's Horizon 2020 research and innovation programme.References

[1] M. Chapa et al., “Realistic MRI phantom for T2 and Quantitative Susceptibility Mapping”, in Proc. Intl. Soc. Mag. Reson. Med. 28 (2020) 4270

[2] F. B. Coulter et al., “Bioinspired Heart Valve Prosthesis Made by Silicone Additive Manufacturing”, Matter 1 (2019) 266–279

[3] ACEO, Wacker Chemie AG, Germany; EnvisionTEC GmbH, Germany; SanDraw Inc, Taiwan

[4] FreeSurfer: surfer.nmr.mgh.harvard.edu, SPM: www.fil.ion.ucl.ac.uk/spm; 3DSlicer: www.slicer.org

[5] D. Kilian et al. “En Route to multiphasic anthropomorphic MR phantoms: An additive manufacturing approach applying bio-printing techniques”, submitted to Intl. Soc. Mag. Reson. Med. 29 (2021)

[6] A. Toria et al. “En route to multiphasic anthropomorphic MR phantoms: A new mold-based approach applying gel-based preparation to real MR-datasets geometries”, submitted to Intl. Soc. Mag. Reson. Med. 29 (2021)

[7] J. K. Barral et al. “A robust methodology for in vivo T1 mapping”, MRM 64 (2010) 1057–1067

[8] G. J. Stanisz et al., “T1, T2 relaxation and magnetization transfer in tissue at 3T”, MRM 54 (2005) 507–512

Figures

Figure 3: a) T1 images of four silicone types determined from complex valued IR-SE data.

b) Signal intensities with standard deviation of corresponding ROIs within the silicone discs for varying echo times TE and a double-exponential fit function applied. The fast and slow relaxation could easily be seen by the kink at around 50 ms.

c) Fit results showing a relative high amount of the slow relaxing spin pool as well as a quite high signal intensity for SF-00. ESA-6018, in contrast, exhibits a very low amount of the slow relaxing spin pool and consequently a relatively small signal intensity.