2268

Damping of acoustic noise for neonatal MRI at 7 Tesla1Radiology, University Medical Center Utrecht, Utrecht, Netherlands, 2Philips HealthCare, Best, Netherlands, 3Otorhinolaryngology and Head & Neck Surgery, University Medical Center Utrecht, Utrecht, Netherlands, 4Neonatology, University Medical Center Utrecht, Utrecht, Netherlands

Synopsis

We designed a new acoustic hood for neonatal MRI exams at 7 Tesla. The new design is lightweight and allows easy access to the neonate during the MRI examination. We were able to optimize the new acoustic hood to a noise reduction of 10.6dB, exceeding the damping of a prototype with damping of 3.1dB. The new hood was designed to fit a head coil and allows the use of a ventilation tube.

Introduction

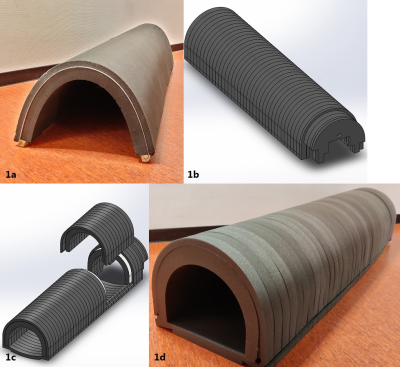

Subjects are often exposed to loud acoustic noise during an MRI exam. This is a well-known cause of discomfort and could potentially lead to hearing damage if protection devices (earplugs/earmuffs/headphones) are not properly used. In neonates, acoustic noise imposes another risk for waking up an infant while scanning, which will most likely lead to a failed examination. Previous research (1)(2) has shown that the acoustic hood may provide additional hearing protection next to headphones, ear muffs or other noise attenuators. In this work, we optimized the design of an acoustic hood, dedicated to neonatal MRI. We compare this final product with a prototype that had been used over the past year (fig. 1a).Methods

The requirements for the neonatal acoustic hood were:- The NOVA Medical (2TX 32RX) RF head coil must be placed inside the hood

- Patient ventilation must be sufficient

- The hood must fit on the table of a 7T Achieva MRI (Philips, Best, The Netherlands)

- In case of an emergency there should be easy access to the patient

- The new product should be easy to handle by a single person

- The new hood should have the same or more noise attenuation as the prototype

- The hood should not generate 1H signal during imaging

The final product was designed in SolidWorks (Dassault Systèmes). It was built with TC-2 sound damping foam (supplied by Easy Noise Control BV) and Polycarbonate arches (supplied by WSV Kunststoffen).

The final product (fig. 1b) consists out of four parts: three parts hood and one mattress. The mattress, made of sound damping foam, was designed to fit exactly on the 7T table. The hood parts, also made of sound damping foam, contain a plastic plate in the middle. The two parts at the feet end and middle part of the bed are arch-shaped. The middle part is designed such that easy access to the neonate is possible (fig.1c).

The part on the head end of the table was designed to closely fit around the NOVA head coil and has its backside closed off as much as possible. It only contains openings for cables and a ventilation tube.

The presence of 1H signal originating from the hood material was evaluated using a non-selective 3D gradient-echo acquisition with ultrashort TE (Philips, 7T).

Acoustic tests

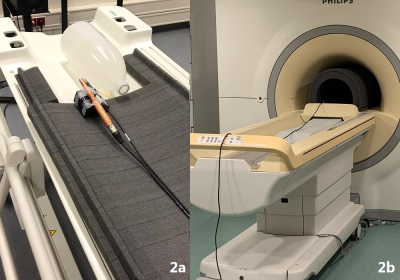

The whole setup was tested twice on noise attenuation. First, the performance of the acoustic hood was evaluated in an acoustic room (ISO 8253-2 2012) (fig 2a). Four loudspeakers were placed around the setup with a microphone at the ear-position. The loudspeakers (Yamaha MSP5) played pink noise and were separately calibrated to a sound level of 70dB(A). Sound levels were recorded with the microphone (Brüel & Kjær 4189 with ZC-0032 amplifier) and measured with a sound level meter (Brüel & Kjær 2250-S). Three measurements were taken from this setup: left-right speakers on, front-back speakers on and all speakers on.

Then, a second test was done inside the 7T MRI to measure the sound level reduction during several scan protocols (fig. 2b). Measurements were done with a microphone (Behringer ECM8000), recorded with Audacity and processed in Matlab (MathWorks). The microphone level had not been calibrated. Therefore, the results inside the MR scanner show relative damping.

Results

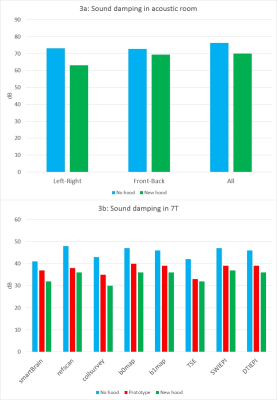

Our final product matches all the requirements. The material did not generate 1H signal during imaging.The acoustic test showed that when the left and right speakers were turned on, the hood damped more than 10dB. When the front and back speakers were turned on, only 3.5dB damping was achieved, resulting in damping of 6.2dB when all speakers were turned on (fig. 3a).

The tests inside the 7T MR scanner (fig. 3b) showed that the acoustic hood damped the acoustic noise during scanning between 9 and 13dB, with an average of 10.6dB. This is 3.1 dB more damping as compared to the prototype acoustic hood.

Discussion and conclusion

We presented a new acoustic hood for neonatal MRI at 7T that damps the acoustic noise between 6 and 10dB. The hood is lightweight and easy to handle by a single person. The new hood achieves an additional 3.1dB damping compared to the previous prototype hood.Acknowledgements

No acknowledgement found.References

1. A. Nordell, M. Lundh, S. Horsch, B. Hallberg, U. Aden, B. Nordell, M. Blennow. The acoustic hood: A patient-independent device improve acoustic noise protection during neonatal magnetic resonance imaging. Acta Paediatr. 2009

2. E. Huijing, K. Rhebergen, P. Stroosnijder, D. Klomp, J. Wijnen, M. Philippens, K. Annink, S. Mandija.Damping of acoustic noise for fetal/neonatal MRI and MR-guided radiotherapy. ISMRM 2020

Figures