1403

Smart Metamaterials for 3T MRI1Fraunhofer MEVIS, Bremen, Germany, 2Fraunhofer FHR, Wachtberg, Germany, 3German Cancer Research Center DKFZ, Heidelberg, Germany, 4MR Imaging and Spectroscopy, Faculty 01, University of Bremen, Bremen, Germany

Synopsis

Smart metasurfaces, special two-dimensional metamaterial devices, have a huge potential to drastically improve imaging efficiency in MRI and are a promising tool to overcome some of the limitations which are hampering technological advances in the field. The design, simulation, and experimental verification of thin, smart, non-linear metasurfaces is presented, which yield an up to eightfold enhanced signal-to-noise ratio in 3T MRI. The smart metasurface is a system of two inductively coupled structures, one of which has a non-linear, incident power-dependent behavior. On-bench characterization and MRI scans with a homogeneous phantom and a kiwi fruit prove the functionality and working principle.

Introduction

Physiological and technological restricts are limiting physically feasible improvements in the field of MRI. There are, e.g., higher static background fields needed for signal-to-noise ratio (SNR) improvements and gradient field switching times limit imaging speed. Both aspects come with subtle challenges making it increasingly difficult to innovate.Metamaterials[4,5] offer a promising solution to advance the efficiency of MRI yielding both, potential sensitivity and speed improvements.[1-3],[6-10] We show that a thin sub-mm signal enhancement plate boosts the SNR up to an eightfold improvement, and the effects are only due to receive (Rx) field enhancements.[1] This plate is a smart (self-detuning), non-linear metasurface. In transmit (Tx), semiconductor components introduce imaging phase sensitivity and detune the structure in order to not affect the Tx field and, thus, assure patient safety. The design makes use of state-of-the-art manufacturing by laser milling. Bulky and multi-slice tunable metamaterial structures, as presented in the literature[2-3],[9-10] are overcome to allow even more possible applications.

Methods

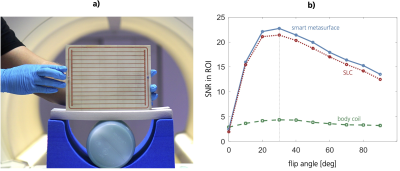

The general idea is to design a metasurface which is i) thin to allow for future flexible, conformal, and patient-specific manufacturing, ii) smart, i.e., ensure patient safety by detuning in the Tx phase of the imaging, and iii) resonant in the Rx phase to yield SNR improvements.Coupled non-linear metamaterials can fulfill these requirements[2] but also additional sensing circuits might be a method of choice.[3] Our metasurfaces - two-dimensional metamaterials - are manufactured on a single 0.508 mm thin PCB (RO4003C, 17 μm-thick Copper layers) and consist of a system of two inductively coupled structures: i) a linear metasurface build as a system of flat, coupled wire-resonator unit cells, and ii) a non-linear diode-loaded loop resonator of which the resonance can also be adjusted via a trimmable capacitor, see Fig. 1. These structures are laser milled onto the substrate. The wire-resonators are strongly coupled to each other and electrically elongated by capacitive end-patches and ground planes on the backside to obtain a resonance frequency at 123.5 MHz, the Larmor frequency of our research scanner (3 T Magnetom Skyra, Siemens Healthineers, Germany).

Via electromagnetic simulations, we develop and iterate the design. CST Microwave Studio is used for Eigenmode and full plane wave simulations. The Eigenmode simulations offer an important tool to match the resonance frequency of the metasurface to the Larmor frequency of a particular MRI system. Plane wave simulations with circular polarization and open boundary conditions allow to include a phantom and simulate the loading.

The functionality is tested on bench by S-parameter measurements and via MRI experiments. For on-bench measurements, untuned sniffer coils connected to a vector network analyzer are used to characterize the smart metasurface depending on the incident power level. The trimmable capacitor in the non-linear tuning loop is used to fine-tune the resonance frequency. For the MRI scans, a gradient echo sequence is used with the following parameters: TR = {100 ms, 1 s}, TE = 5 ms, field-of-view = 256 x 256 mm2, matrix size = 128 x 128, slice thickness = 5 mm, slice distance = 15 mm. Imaging is done with i) the scanner’s body coil, ii) the body coil + smart metasurface, and iii) a local 7 cm single-loop coil (SLC).

Results

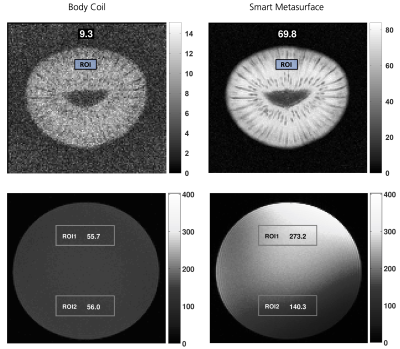

In Fig. 1, the smart metasurface prototype is shown together with SNR results for different nominal flip angle measurements. Fig. 2 shows an exemplary result for images with a homogeneous phantom and a kiwi fruit recorded with i) the scanner’s body coil, ii) the body coil in combination with a smart metasurface.Discussion

On-bench measurements of the scattering parameters S11 and S21 as functions of the incident power prove the working principle for two manufactured prototypes. Below a certain incident power, the smart metasurfaces are resonant at the design frequency, whereas above the threshold the self-detuning behavior shifts the resonance such that they remain ‘silent’.MRI experiments with homogeneous phantoms and a kiwi fruit clearly validate the functionality. Flip angle measurements, see Fig.1, show that the Ernst angle remains constant, i.e., the Tx field is not influenced and patient safety is assured. Moreover, the data shows an eightfold SNR improvement in layers close to the metasurface for scans of the kiwi fruit with TR = 1 s. In contrast to the exponential fall-off behavior of the SLC sensitivity, the SNR enhancement due to the metasurface falls off only linearly in the imaged region.

Conclusion

Being a comparatively young research field, metamaterials in MRI have a huge potential and are a promising tool to tackle some of the challenges that hamper advancements in the field. They offer the possibility to increase the SNR significantly without the immediate need for higher field strengths and to speed up the imaging. Patient safety can be assured due to the automatic detuning mechanism that does not need any manual influence or complicated sensing circuits.The design of thin, non-linear metasurfaces as presented here allows for future patient-specific and flexible conformal manufacturing tailored to particular applications. The bulky design of tunable metamaterials for MRI, as presented in the available literature, is overcome to improve patient comfort and allow for an even wider range of applications.

Acknowledgements

This work was supported by the Fraunhofer MAVO project MetaRF. The authors want to thank Peter Erhard for discussions and comments and Michael Jaeger for support in the production of prototypes.References

[1] Stoja E, Konstandin S, Philipp D, et al. Boosting Magnetic Resonance Imaging with Safe, Smart, and Ultra-Thin Metasurfaces, 2020 (to be submitted)

[2] Zhao X, et al. Intelligent metamaterials based on nonlinearity for magnetic resonance imaging. Advanced Materials. 2019, Vol. 31, 1905461.

[3] Saha D, et al. A smart switching system to enable automatic tuning and detuning of metamaterial resonators in MRI scans. Sci Rep. 2020, Vol. 10, 10042.

[4] Vesselago V G The electrodynamics of substances with simultaneously negative values of ε and μ. Soviet Physics Uspekhi. 1968, Vol. 10, 4.

[5] Pendry J B, Schurig D, Smith D R Controlling electromagnetic fields. Science. 2006, Vol. 312, 5781.

[6] Freire M J, et al. On the applications of μ = -1 metamaterial lenses for magnetic resonance imaging. Journal of Magnetic Resonance. 2010, Vol. 203.

[7] Duan G, et al. Boosting magnetic resonance imaging signal-to-noise ratio using magnetic metamaterials. Communications Physics. 2019, Vol. 2, 35.

[8] Slobozhanyuk A P, et al. Enhancement of magnetic resonance imaging with metasurfaces. Adv. Mater. 2016, Vol. 28.

[9] Shchelokova A V, et al. Locally enhanced image quality with tunable hybrid metasurfaces. Phys. Rev. Applied. 2018, Vol. 9, 014020.

[10] Kretov E I, Shchelokova A, Slobozhanyuk A P Control of the magnetic near-field pattern inside MRI machine with tunable metasurface. Appl. Phys. Lett. 2019, Vol. 115, 061604.

Figures