4267

Quantification of microscopic spatial resolution on MR-scanners using micro-phantoms manufactured with Deep-Xray Lithography1Center for Medical Physics and Biomedical Engineering, Medical University of Vienna, Vienna, Austria, 2Karlsruhe Nano Micro Facility (KNMF), Karlsruhe Institute of Technology (KIT), Eggenstein-Leopoldshafen, Germany

Synopsis

Quality control for systematic improvements in spatial resolution up to the microscopy range becomes increasingly relevant not only for preclinical imaging but also for High Field MR human scanners. The design, manufacturing technology, a prototype phantom and an exemplary evaluation for qualitative and quantitative measurement of the spatial resolution of MR-scanners claimed to offer spatial resolutions better than 100µm is presented. The spatial resolution for 2D-FT anisotropic imaging can be checked qualitatively and quantitatively by interpolation of the Modulation-Transfer-Function in two different spatial encoding directions at the same time with slice-thickness below 120µm up to 64 line-pairs/mm (pixel-size: 8µm).

Purpose and Introduction

The improvements in methodology of spatial encoding (e.g. sensitivity encoding by multichannel rf-coils), hardware in connection with optimized pulse sequence protocols for targeted organs in principle allow for high nominal spatial resolution in MRI with isotropic pixel-sizes in the microscopic range (ps<100x100µm2), not only on preclinical animal and investigational vertical high-field MR-microscopy devices but also recently even on human MR-scanners. However the spatial resolution of an MR-imaging device is only restricted ultimately by the voxel size; the actual spatial resolution is dependent on several different technical and sample specific features, e.g. signal-to-noise ratio (SNR), line width (T2), susceptibility and chemical shift differences, gradient-strength available, gradient switching behaviour and shimming performance. Further improvements in methodology, hard-/software and proof of resolution quality demand for standardized objective quality control on the actually achieved spatial resolution instead of simple voxel size criterions. Concepts for the quantitative measurement of spatial resolution are based on the Line-Spread-Function (LSF) and Modulation-Transfer-Function (MTF)1. Design proposals for standardized resolution phantoms for slice-selective 2D-FT do exist2,3. However, the proposed protocols and phantoms are designed and prescribed for minimum sized structures typically down to about 0.7 mm 3. Proposals and realizations for phantoms do exist for proving spatial resolution up to 5 line-pairs (lp) per mm in one spatial encoding direction4, but the corresponding plate-thickness of 100µm still does not allow for the proof of resolution with pixel-sizes<100µm as possible on preclinical and recently also on human MR-scanners. We here present an investigational resolution-phantom and evaluation concept, which allows not only for a quick qualitative check on actually obtained spatial resolution with periodic micro-structures down to 8µm, but also the quantitative evaluation of the MTF up to about 64 lp/mm based on a set of grids with varying periodicity. The demands on spatial accuracy, aspect-ratios, duty-cycle, reproducibility and mechanical stability on these micro-structures (phantoms) including lamellae of 140µm depth at 1µm thickness have been ambitious. The design concept, manufacturing based on micro-structuring technology, evaluation procedure and an example of MR-evaluation are shown within this contribution.Subjects and Methods

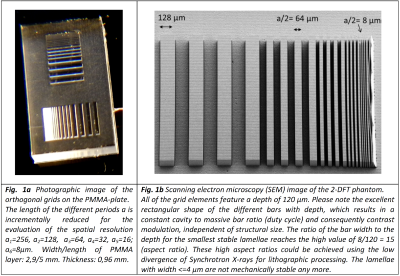

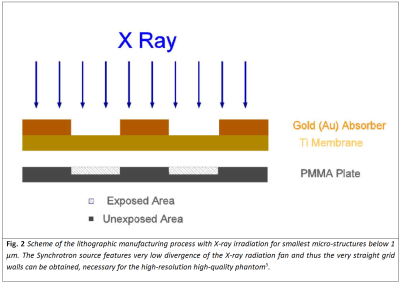

The phantom-design is based on standard proposals for the quality control on human scanners featuring a range of grid structures with reducing periods2,3 (fig. 1). With difference, the proposed test-device covers periodic structures between periods of a1=256 down to a8=2µm for the coverage of spatial resolution up to the best-performing MR microscopy scanners. The design is optimized for 2D-FT pulse sequences with high in-plane resolution at comparable high slice-thickness. Two orthogonal grid sets for independent analysis of e.g. phase and frequency encoding direction feature strongly anisotropic grid bars (fig. 1b) with lamellae depth to lamellae width (aspect ratio) better than 10. However such anisotropic micro-phantoms can only be obtained by special micro-manufacturing technologies as deep X-ray lithography (fig. 2) featuring high dose rates and very low divergence. The corresponding challenge was met using a Synchrotron source at KNMF (KARA, KIT, Karlsruhe, Germany), available for research5.Results

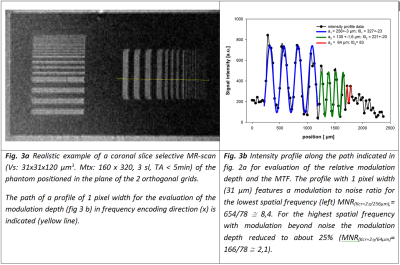

As a result of several optimizing manufacturing set-ups with different PMMA structural depth we obtained a prototype phantom with structural depth of 120µm featuring mechanically stable lamellae with width between a1/2 = 128 down to a5/2 = 8µm (aspect-ratio: 15). Excellent duty-cycles (ratio of cavity to bar-width) close to 1 and straight grid walls are obtained (fig. 1b). The phantom was checked for its suitability for qualitative and quantitative quality control on the spatial resolution using a slice-selective 2D-FT spin-echo pulse sequence with a pixel-size of 31x31µm2 at slice-thickness of 120µm (SNR6 ≈ 8,5; fig. 3). The MR-measurements are performed on a High-Field (B=7T) human MR-scanner using a micro-imaging insert7. The slice could be adjusted to the layer of the 2D-grid such, that both of the orthogonal grids could be observed (fig. 3a). Visual qualitative inspection in vertical direction indicates, that the grid period of a3=64µm (lamellae-width a3/2 =32µm) could be differentiated. However the same grid in horizontal direction is hardly to be visualized at pixel-size of 31µm. The evaluation of the relative modulation depth for the corresponding profile with fitting of the pixel position to the grid modulation phase yields a value Mr = 0.25. According to the resolution criterion (Mrmin=0,5!)8 this structure is not resolved. By interpolation of the MTF the resolution can be quantified (Mr(Kres)=0,5!): Kres≈10.4 lp/mm; resolution: a/2 ≈ 48µm.Discussion/Conclusion

The conceptual design of a prototype phantom for quick qualitative and quantitative checking of the spatial resolution for the MR-microscopic range in two independent spatial encoding directions is presented. The orthogonal sets of grids are designed for slice-selective MRI with anisotropic voxels with pixel-size between 128 and 1µm. A prototype phantom for this design using Deep-Xray-Lithography and Synchrotron irradiation was manufactured. The second level optimized prototypes featured smallest lamellae width of 8µm. The application of the evaluation concept is demonstrated on an example for slice-selective 2D-FT microscopy on a human high-field MR-scanner with a micro-imaging insert, showing quantitatively the difference between pixel-size and actual spatial resolution. Prototype phantoms can be borrowed from the author for quantitative checks of MR-apparatus for objective quality control, proof of spatial resolution, hardware and software improvements.Acknowledgements

This project was supported by the Karlsruhe Nano Micro Facility (KNMF); project nr. 2015-013-006488; A. Berg; 2-3-Dimensional μ-Structures for Magnetic Resonance Microscopy.References

1 Rossmann K; Point Spread-Finction; Line Spread-Function and Modulation transfer function; Radiology 93, 257- 272 (1969).

2 European Norm EN 61223-3-7 (IEC 62B/575/CDV) 2005.08.01; Evaluation and routine testing in medical imaging departments; Part 3-7: Acceptance and constancy tests – Determination of essential image characteristics of magnetic resonance equipment (2005).

3 American College of Radiology; MR accreditation program; Testing Instructions, small phantom guidance (2018) (https://www.acraccreditation.org/-/media/ACRAccreditation/Documents/MRI/SmallPhantomGuidance.pdf).

4 Fellner C, Muller W, Georgia J, Taubenreuther U, Fellner FA, Kalender WA; A high-resolution phantom for MRI; Magnetic Resonance Imaging 19, 899–904 (2001).

5 Saile V, (ed.), Wallrabe U, (ed.), Tabata O (ed.), Korvink JG (ed.); LIGA and its applications; in: Advanced Micro & Nanosystems 7, 1; Wiley-VCH (2009) ISBN 978-3-527-31698-4.

6 Henkelman, RM; Measurement of signal intensities in the presence of noise in MR images; Med. Phys.12, 232-233 (1984).

7 Berg A, Potthast A, Starewicz P; MR-MICROSCOPY ON A HUMAN 7T-SCANNER; Proc. ISMRM 2010, progr nr. 1048, Stockholm, Sweden, 01.-07.05.2010 (2010).

8 Lerski RA, de Certaines JD; II Performance assessment and quality control in MRI by Eurospin test objects and protocols; Magnetic Resonance Imaging 11 (6) 817-833 (1993).