4204

Gradient dB/dt Heating Measurements of a Copper Annulus Reference Standard Using a Laboratory dB/dt Exposure System1Physics and Astronomy, Western University, London, ON, Canada

Synopsis

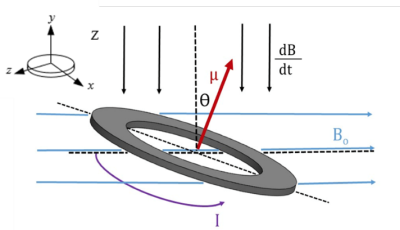

Standardized testing in the field of MR Safety is critical to the functioning of the science and the well-being of the patient. The gradient-induced temperature rise of a copper annulus reference standard was measured using a laboratory dB/dt exposure system to assess measurement repeatability and validation of test system operation. The reference standard was subjected to heating variables, including gradient exposure in various gelled-HEC temperatures and gradient exposure to various frequencies of magnetic field. Results indicate the effect of eddy currents on conductive materials under various testing conditions, which is of significance for passive and active implantable medical devices.

Introduction

The gradient-induced temperature rise of three MRI-compatible metals of varying thicknesses and inner diameters were measured using a laboratory dB/dt exposure system to assess measurement repeatability, and to further identify a reference standard for validation of test system operation.1 After a reference standard was identified, it was subjected to various frequencies and various gelled hydroxyethyl cellulose (HEC) temperatures to assess measurement repeatability across different possible testing conditions. The metal annulus chosen to be a suitable reference standard for use in a dB/dt exposure system was determined after months of data collection and measurement repeatability from the previous year, and consists of copper-C110, a thickness of 1.5-mm, an inner diameter of 40-mm, and an outer diameter of 50-mm.1Methods

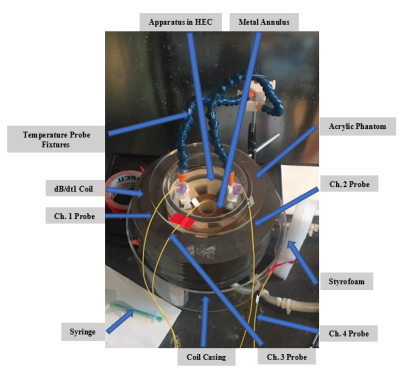

The reference standard was held into position by an apparatus printed three-dimensionally. The apparatus was designed to firmly fit into the 11.4-cm (5-inch) inner diameter of the phantom, which was then inserted into the dB/dt-1 coil. The phantom was filled to a height of 9-cm with gelled HEC phantom material.2 After the gelled HEC was poured into the phantom with the reference standard in its apparatus, a needleless syringe was placed over top of each of the 1-mm holes of the reference standard, extracting any air bubbles prior to inserting fiber optic temperature probes into the 1-mm holes. A water-cooled electromagnet, an amplifier (Copley Controls Corp., Model 266), and a function waveform generator were integrated into the dB/dt exposure system and used to create gradient dB/dt field exposures as specified in Clause Nine.3The reference standard underwent six repeated exposures totaling 12 temperature readings. Each trial involved 20-seconds of gradient exposure followed by 160-seconds of cooldown time. Two fiber optic temperature probes (Neoptix Inc., T1C-15548A) were fixed into position by three-dimensionally printed structures that held the temperature probes in place within the gelled HEC. A third probe was placed in the gelled HEC ensuring the media did not significantly heat up and lose its thermal properties during gradient exposure. A fourth probe was placed on the boundary surrounding the dB/dt-1 coil measuring the ambient temperature, ensuring tests were being conducted in a thermally stable environment. A piece of Styrofoam was used to further isolate the ambient temperature sensor to ensure minimal environmental temperature change. Limitations exist when a phantom and a gradient-field coil are being used to simulate gradient-field exposure of a clinical, MR gradient field. To minimize possible variations in temperature readings due to phantom movement, pieces of Styrofoam were placed between the phantom and the inner boundary of the gradient coil to situate the phantom firmly in the centre of dB/dt-1 coil. The system software used was ‘dB by dt System 32bit with SOS with Neoptix’.

Results

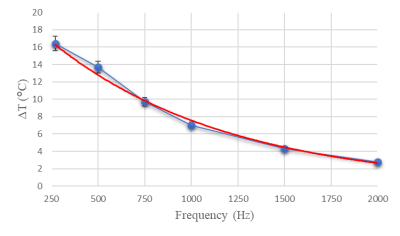

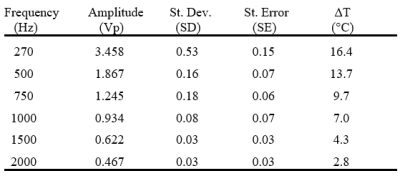

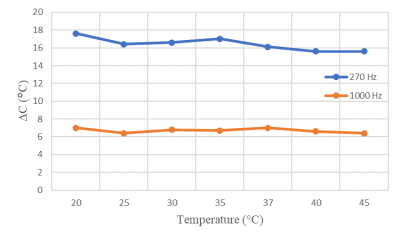

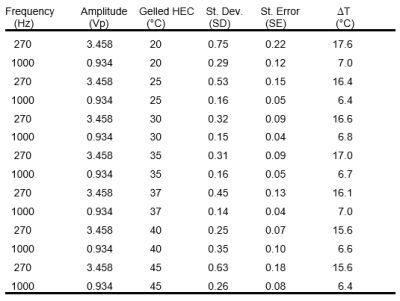

The reference standard was subjected to six different dB/dt exposures. A continuous 270, 500, 750, 1000, 1500 and 2000 Hz sinusoidal wave were produced, each with a continuous dB/dt value of 42 T/s rms. Six trials (i.e.,12 temperature readings) were collected in total at each frequency produced.The reference standard was also subjected to dB/dt exposure at seven different gel temperatures ranging from 20 to 45 °C at both 270 Hz and 1000 Hz. The gelled HEC was heated using a water bath tank (i.e. Techne FBATH26) with thermoregulator (i.e. Techne Tempunit TU-20D). Temperature of the gel was measured using a NIST traceable calibrated resistance temperature detector (RTD) thermometer (i.e. ThermoProbe TL1-R). The thermometer verified the temperature that the water bath was reading, alongside the temperature of the gelled HEC. The gelled HEC was placed in a Tupperware container. The lid was placed on the Tupperware, and the rim of lid was lined with duct tape to ensure water did not enter the container and alter the chemistry of the gelled HEC. The gelled HEC was heated to ± 0.5°C of the desired temperature to be tested by placing the Tupperware in the water bath.

Discussion

Regression of the temperature change was high across frequencies, where y=-0.0079x+16.87 with an R2 value of 0.91 (Figure 2), indicating dB/dt heating of the reference standard decreases as a function of increased frequency at a continuous dB/dt value of 42 T/s rms.The gelled-HEC temperature remained ± 0.5ׄ°C of the desired temperature to be tested across the six trials (Figure 3). The gelled-HEC temperature was measured by the channel three temperature probe placed inside the gelled HEC (Figure 1). HEC solutions are most stable below 60 °C and at shorter times of thermal stress at higher temperatures. At low temperatures (under 100 °C), the thermal destruction of cellulose does not usually set in, but many properties and appearance of the substance changes.4 The degree of heating of the copper annulus did not significantly differ when the starting temperature of the gel was heated up to 45°C at either 270 or 1000 Hz, as supported above.4

Conclusion

These findings further assist in the safety and reliability of a dB/dt exposure system simulating the magnetic field properties of an MRI scanner under various testing conditions. Further research involves validating dB/dt heating with the copper annulus reference standard under the dB/dt exposure system parameters using a 3T MRI scanner at Robarts Research Institute.Acknowledgements

This work was funded by NSERC Industrial Research Chairs Program, Ontario Research Fund Research Excellence Program, and Canadian Foundation for Innovation.References

1. Crane J, et al. Gradient dB/dt heating measurements of copper, steel, and titanium annuli: Assessment of measurement repeatability, and identification of a potential reference standard. http://archive.ismrm.org/2019/4200.html. Accessed November 5, 2019.

2. ASTM F2182-11a; 2008.

3. ISO/TS 10974; 2018.

4. Blazkova A, et al. Viscosity properties of aqueous solutions of hydroxyethylcellulose. Сhem Pap. 1990;44(3):289-301.

Figures