4085

Integrating RF coil with low-loss tuHDC ceramics at room temperature for large improvements in B1 fields and SNR, denoising for UHF 23Na MRSI1Department of Radiology, CMRR, University of Minnesota Medical School, Minneapolis, MN, United States, 2Department of Engineering Science and Mechanics, The Pennsylvania State College of Engineering, University Park, PA, United States, 3CNMRR, Department of Neurosurgery, The Pennsylvania State College of Medicine, Hershey, PA, United States

Synopsis

Integrating ultrahigh-dielectric constant (uHDC) materials with RF coils have improved MR imaging performance. In this work, we present a novel approach based on the permittivity tunable (tuHDC) ceramics, which has an extremely high tunability of permittivity from 2000-15000 by changing the ceramic temperature between few to 40 °C, for 23Na MRSI at UHF. We demonstrate that the optimal temperature and performance of the tuHDC ceramic for 23Na MRSI at 7T was at room temperature. We report spatially dependent increases in the RF transmission and reception fields and SNR with a large factor of ~4 accompanied by moderate global denoising effect.

Introduction

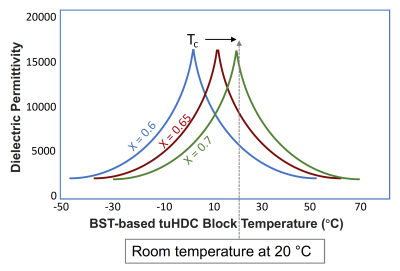

Sodium (23Na) MRI provides abundant information about human physiology and metabolism, which could significantly improve diagnosis and management of diseases such as stroke and tumor.1 Ultra-high field (UHF) strength is powerful in improving MRI sensitivity and resolution,2,3 which could also benefit from dielectric metamaterials.4-6 In this study, we present a new RF engineering approach based on permittivity-tunable ultra-high dielectric constant (tuHDC) ceramics for advancing MRI at UHF. For proof of concept, we exploit the tuHDC-RF coil technology for greatly improving 23Na MRSI at 7T. The tuHDC ceramic was made from barium-strontium (BST) composite compounds (BaxSr1-xTiO3, x: Ba/Sr ratio, 0<x<1). Thus, the relative permittivity (εr) of the BST-tuHDC ceramics is sensitive to the ceramic temperature and has a very large tuning range from 2000 at ~40 °C up to > 10000 at few °C, offering a powerful utility for robust optimization for broad MR imaging application.Materials and Methods

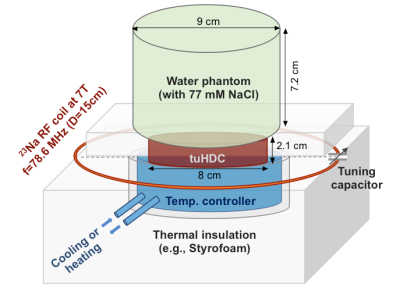

BST-based tuHDC ceramics (circular shape, 8 cm diameter, 2.1 cm thickness) were manufactured (x=0.6, Ba0.6Sr0.4TiO3) having a low dielectric loss tangent (tanδ < 0.025) and ultrahigh εr of 4500-4700 at room temperature (20 °C) and an ideal operating frequency below 100 MHz.7-9 The BST stoichiometry (x) controls the relationship between εr and ceramic temperature according to the Curie-Weiss law above which the ceramics is in a beneficial paraelectric state.MRSI experiments were carried out on a Siemens 7T whole-body/90-cm bore human scanner (SiemensHealthineers, Erlangen, Germany) with a single-loop 23Na RF coil (15-cm diameter) tuned/matched at 78.6 MHz. A cylindric-shape bottle (9 cm inner diameter and 7.2 cm height) was filled with saline water (77 mM NaCl). The tuHDC ceramics was placed at the RF coil center underneath the water phantom and above a temperature controller and was surrounded by Styrofoam (Figure 1). Temperatures were allowed to equilibrate at each series of MRI-acquisitions before they were scanned. 3D 23Na-CSI data sets were acquired under fully relaxed condition with following parameters: TR = 0.3 s, RF (hard) pulse width = 2 ms, 3D phase-encoding matrix size = 9×9×7, spectral bandwidth = 10 kHz, FOV = 10×10×10 cm3, number of complex data points of FID = 512, various RF pulse flip angles by adjusting RF transmitter power voltage, and no signal averaging. Post-processing of the voltage-dependent image series for B1 estimation was performed in custom-built Matlab scripts by sinusoidal fitting and normalization.

Results

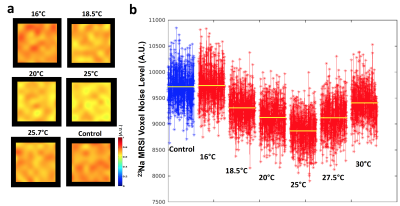

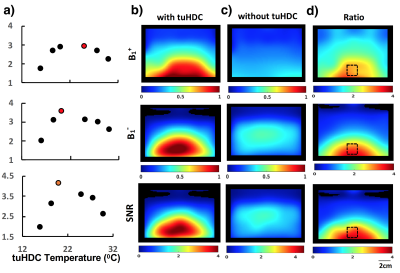

Figure 2 presents the comparison results of 23Na MRSI noise maps when placing the tuHDC ceramics between the RF coil and the sample, showing a significantly lower (-10%) spectral noise level at the ceramic temperature of ~25 °C in contrast to without the tuHDC ceramics (Fig. 2b). Analysis of central 2D CSI slice maps of the raw noise levels shows no spatial dependence in the observed noise reduction (Fig. 2a), suggesting a global denoising effect. Very high increases of B1+ efficiency of up to 200% were observed (Fig. 3, upper row) and even higher in B1- sensitivity (>250%, Fig. 3, middle row) in close proximity to the tuHDC block and in the center of the RF coil plane. The B1 field-increasing effects were higher around room temperature (20 °C) similar to the behavior of the denoising effect (Fig. 2b versus Fig. 3a). The temperature dependence of the B1+, B1- and signal-to-noise ratio (SNR) ratios between with and without the use of the tuHDC block were similar and reached a maximum at the room temperature (20 °C) as shown in Fig. 3a. In consequence, the combination of both increased B1- receive sensitivity and denoising effect resulted in a strikingly large SNR improvement of up to ~4 times compared to control (Figure 3, lower row). The permittivity (εr) of the tuHDC ceramics at room temperature (20 °C) was 4500-4700.Discussion and Conclusions

The large improvements of B1+ and B1- and denoising effect observed in this study resulting in an overall SNR boost of up to a factor of 4 clearly show the promising tuHDC-application to 23Na MRSI/MRI at UHF. It is remarkable that the highest benefits were occurring around a region where the self-resonance of the tuHDC and the RF coil were coupled most effectively. The practical benefit in conclusion of this study is the successful operation of the BST-based tuHDC in an optimized condition around room temperature, thereby enabling easy integration with RF coils and no need for controlling the ceramic temperature in order to achieve an optimal performance. The large SNR improvement for 23Na MRSI achieved at 7T has reached an equivalent performance beyond the highest field strength available, 10.5T, for human studies. Since the optimization of the tuHDC technology is determined by the Larmor (or RF-operating) frequency and optimal εr, we anticipate similar and superior improvements for in vivo 13C MRS application at 7T because the Larmor frequency of 13C and 23Na are nearly the same. Another merit of the BST-tuHDC technology is the flexibility in shifting the relationship between the ceramic temperature and permittivity as schematically illustrated in Fig. 4 by changing the composite ratio (x) to a desired value, thus, allowing best performance at room temperature. In summary, the new tuHDC technology offers a low-cost and effective RF engineering solution for broad biomedical MR imaging applications.Acknowledgements

This work was partly supported by NIH Grants U01 EB026978, R24 MH106049, R01NS070839, R01 CA240953, R01 MH111413, S10 RR029672 and P41 EB027061.References

1. Thulborn,

K. R. Quantitative sodium MR imaging: A review of its evolving role in medicine.

Neuroimage 168, 250-268, (2018)

2. Ugurbil,

K. et al. Ultrahigh field magnetic resonance imaging and spectroscopy. Magnetic

resonance imaging 21, 1263-1281, (2003)

3. Nowogrodzki,

A. The world's strongest MRI machines are pushing human imaging to new limits.

Nature 563, 24-26, (2018)

4. Yang,

Q. X. et al. Manipulation of image intensity distribution at 7.0 T: passive RF

shimming and focusing with dielectric materials. J Magn Reson Imaging 24,

197-202, (2006)

5. Park,

B., Webb, A. G. & Collins, C. M. A method to separate conservative and magnetically-induced

electric fields in calculations for MRI and MRS in electrically small samples.

J Magn Reson 199, 233-237, (2009)

6. Rupprecht,

S., Sica, C. T., Chen, W., Lanagan, M. T. & Yang, Q. X. Improvements of

transmit efficiency and receive sensitivity with ultrahigh dielectric

constant(uHDC) ceramics at 1.5 T and 3 T. Magnetic Resonance in Medicine 79,

2842-2851, (2017)

7. Tagantsev,

A. K., Sherman, V. O., Astafiev, K. F., Venkatesh, J. & Setter, N. Ferroelectric

materials for microwave tunable applications. Journal of Electroceramics 11,

5-66, (2003)

8. Zhang,

J. J., Shen, B., Zhai, J. W. & Yao, X. Microwave Dielectric Properties and Low

Sintering Temperature of Ba0.5Sr0.5TiO3–Mg2TiO4 Composites Synthesized In Situ

by the Hydrothermal Method,. Ceram. Int. 39, 5943–5948, (2013)

9. Sengupta,

L. C. & Sengupta, S. Breakthrough advances in low loss, tunable dielectric

materials. Material Research Innovations 2, 278-282, (1999)

Figures