3247

A low-cost, versatile phantom for elastography: validation via numerical simulations and MRE1Laboratory for Adaptable MRI Technology (AMT lab), Dpt of Biomedical Engineering, University of Basel, Allschwil, Switzerland, 2Medical Image Analysis Center (MIAC AG), Basel, Switzerland, 3Quantitative Bioimaging Group (qbig), Dpt of Biomedical Engineering, University of Basel, Allschwil, Switzerland

Synopsis

We describe the fabrication of a low-cost, silicone-based phantom for elastography, which provides precise geometries and controlled stiffness. Simulations were carried out to produce synthetic MRE data and verify the performance of MRE reconstruction in ideal conditions. To our knowledge, this is the first time that simulations can be validated on exact same physical objects, making this approach very handy to optimize acquisition parameters and establish reconstruction validity criteria of elastography data. Such phantoms can be prepared with different mechanical properties, and could thus be broadly used as an accessible mean to assess the robustness of MRE tools.

Introduction

Elastography is an imaging technique that assesses the stiffness of body tissues remotely1,2. Several elastography approaches exist that involve complex combinations of many interdependent elements (vibration source, motion capture, reconstruction algorithm). Hence, it is paramount to assess the accuracy of elastography protocols in phantoms before applying it to patients, or before drawing diagnostic or research conclusions.Commercial phantoms are usually optimized only for ultrasound elastography and are very expensive despite their lack of stability over time. Typical elastography materials used for custom phantoms have different drawbacks: water-based polymers lacking long-term stability, irregular geometries and/or inhomogeneous mechanical properties3.

We propose to use a low-cost, silicone-based material for custom-built elastography phantoms, which provides precise geometries and desired stiffness properties in a reproducible way. We show that our reconstruction algorithm can be validated by comparison with MRE results of ideal synthetic data, simulated on a ground-truth phantom.

Methods

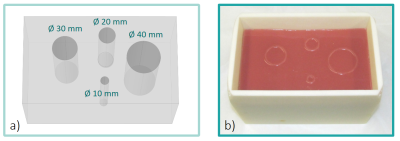

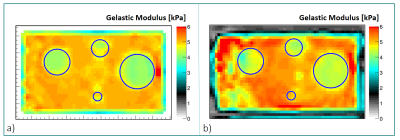

Simulations of a CAD-designed ground-truth phantom were done using the Structural Mechanics module of COMSOL Multiphysics© (COMSOL AB, Sweden). The phantom comprises 4 inclusions in a homogeneous background (Fig 1a: cylinders of diameters 10, 20, 30, and 40 mm), and viscoelastic parameters were set in the software (background: Gd = 5.1 kPa, Gl = 1.5 kPa; inclusions: Gd = 4.1 kPa, Gl = 1.4 kPa). Wave propagation was simulated using a FEM forward approach for a given frequency (57 Hz) and the displacement fields were extracted at the resolution employed in MRE (3 x 3 x 3 mm3 voxels, 9 slices). This information was converted into synthetic raw phase data that was processed by curl-based direct inversion algorithm4.The physical phantom was made using a custom 3D-printed cast and a bicomponent RTV silicone Eurosil4 with the addition of a Eurosil Softener (Schouten Syntec, Netherlands). Firstly, the background was created by filling the mold (182 x 108 x 105 mm3) with the first silicone mixture (ratio by weight 1A : 1B : 1.75 Softener) with solid 3D-printed cylinders (Ø 10, 20, 30, 40 mm) positioned inside. After 1 day of curing time, the cylinders were extracted and the remaining holes were filled with a second mixture (1A : 1B : 1.9 S) to create softer inclusions. At the beginning of the curing process, the silicone was degassed in a vacuum chamber.

MRE was performed at 3 T (Prisma – Siemens, Germany), using a custom 57 Hz vibration source5 and a fractional gradient-echo encoding sequence6. The phantom was positioned in its cast to constrain the lateral faces’ movement, and the acoustic vibration created at its surface. A 32-channel head coil was used for the experiments. Raw data were processed using the same method used for the synthetic data.

Results

The silicone used for the phantom yields accurate and precise contours of the inclusions (Fig 1b). No discontinuity arises between the background and the inclusions as seen from the MR images (data not shown), which ensures continuous wave propagation. Furthermore, the material preserves its geometric shape without any visible degradation after 5 months.The elastograms obtained from the simulation (Fig 2a) clearly show the inclusions with stiffness values corresponding to the desired parameters. On the elastograms of the physical phantom (Fig 2b), the three largest inclusions are correctly detectable. In both elastograms, non-homogeneous regions are present both in the background of the phantom and in the inclusions.

Discussion

We showed that our silicone-based material enables the fabrication of objects with precise contours, helping to assess, for a given elastography protocol, the minimum detectable object size, which can be extremely useful for the detection of focal lesions such as tumors. This phantom can be used in parallel to simulations assessing the performance of the reconstruction method for different elastography protocols, by varying for example spatial resolution and/or vibration frequency.The elastogram obtained in the physical phantom showed a central spot with higher stiffness that is due to strong waves in the region in contact with the vibration source. One can also observe that the left side of the elastogram is very heterogenous and this is due to poor wave propagation in this area. The next step would consist in determining confidence values for our elastograms based on those considerations.

Finally, in order to obtain stiffness values comparable to biological tissues, we had to use softener concentrations higher than what the material is designed for. This caused a slight leakage of the oil softener, which might alter the phantom’s mechanical properties over time. Further investigations will include rheological studies to assess the mechanical stability of the silicone and fully characterize the relation between the desired stiffness and the material composition.

Conclusions

We showed that it is possible to fabricate a silicone-based phantom with materials that are cheap, easy to handle, and stable over time. Those phantoms can be prepared with different mechanical properties and consist in a convenient tool for MRE methods’ validation.To the best of our knowledge, this is the first time that simulations can be validated on exact same physical objects, making this approach very useful for optimizing acquisition parameters and establishing reconstruction validity criteria of elastography data.

Acknowledgements

No acknowledgement found.References

1. Muthupillai R, Lomas D, Rossman P, et al. "Magnetic resonance elastography by direct visualization of propagating acoustic strain waves." Science (80- ). 1995;269(5232):1854-1857.

2. Krouskop TA, Dougherty DR, and Vinson FS. 1987. “A Pulsed Doppler Ultrasonic System for Making Noninvasive Measurements of the Mechanical Properties of Soft Tissue.” Journal of Rehabilitation R&D 24 (2): 1–8.

3. Solamen LM, McGarry MD, Tan L, et al. 2018. “Phantom Evaluations of Nonlinear Inversion MR Elastography.” Physics in Medicine & Biology 63 (14): 145021.

4. Sinkus R, Tanter M, Xydeas T, et al. 2005. “Viscoelastic Shear Properties of in Vivo Breast Lesions Measured by MR Elastography.” Magnetic Resonance Imaging 23 (2 SPEC. ISS.): 159–65.

5. Salameh N, Souris L, Sarracanie M, et al. 2011. “Feasibility of Brain MR-Elastography at 1.5 T with a Novel Wave Generator : An Animal Study” Proc ISMRM2011: 3492.

6. Garteiser P, Sahebjavaher RS, Ter Beek LC, et al. 2013. “Rapid Acquisition of Multifrequency, Multislice and Multidirectional MR Elastography Data with a Fractionally Encoded Gradient Echo Sequence.” NMR in Biomedicine 26 (10): 1326–35.

Figures