4071

Development of a standard reference object for monitoring quality and reproducibility in dB/dt-heating tests for medical devices1The xMR Labs, Department of Physics and Astronomy, Western University, London, ON, Canada

Synopsis

The intent of this study is to introduce and characterize a standard reference object for gradient-induced dB/dt heating studies. Key attributes of a standard reference object would be simplicity, sensitivity (large response to exposure conditions), and reproducibility. Various geometries, materials, and exposure conditions were studied, and the results indicate the temperature rise of a simple copper annulus can be used to verify all components of a dB/dt exposure and measurement system are functioning prior to a device test. The thermal response of a 5-cm diameter copper annulus was characterized as a function of frequency and dB/dt-amplitude, both in air and in tissue-mimicking gel.

Introduction

Gradient-induced time varying eddy currents can cause heating, motion, or the malfunction of medical devices in an MR scanner. Standardized device testing is critical in ensuring consistent results between different methods and laboratory groups. For radiofrequency heating tests of devices, ASTM F2182-11a specifies the use of a standard titanium rod for measuring the local specific absorption rate (SAR) due to RF exposure in a test location1. New test methods under development, such as ISO DTS-109742, specify methods for dB/dt exposure testing of devices, but do not propose standard objects for use with those tests. At present, no such standard object exists for characterizing and monitoring dB/dt exposure conditions.Methods

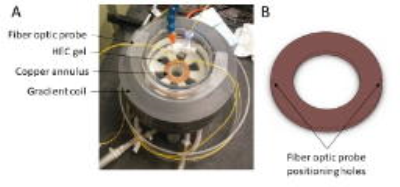

The dB/dt induced heating of copper, stainless steel, and titanium annuli with 50 mm outer diameter, 30 mm inner diameter and 3 mm thickness was compared. Two 1 mm diameter holes were drilled from opposite ends of each annuli, centered 1 mm away from the outer edges to position temperature sensors. A fixture made of polycarbonate plastic was 3D printed to center and hold the annuli in place to minimize positional errors. Each metal annulus was tested in both air and Hydroxyethylcellulose (HEC) gel to determine the temperature rise due to a 1 minute exposure at 42 T/sRMS and 270 Hz, per the ISO DTS 10970 standard requirements2. Due to its high electrical conductivity, copper was chosen to compare the effect of dB/dt (5, 10, 20, 42 T/sRMS) and frequency (270, 500, 1000 Hz). An additional 10 repeats were performed at 42 T/sRMS and 270 Hz with a single copper annulus in HEC gel to determine measurement repeatability.

A solenoid electromagnet made with 12 axial windings and 6 radial windings of hollow, square, copper wire, with an efficiency of 0.454*10-3 mT/A, was used to induce a gradient field (Figure 1). The field was controlled and monitored using Labview software controlling a high-power amplifier (Copley Controls Corp. Model 266). Laser fiber temperature probes (Neoptix Inc., T1C-15548A) connected to a Neoptix ReFlex system were placed inside the designated holes at the edge of the annuli to measure temperature change throughout a 1 minute exposure. The maximum temperature rise was extracted and the average and standard deviation of the 2 temperature sensors was calculated and compared between conditions.

Results

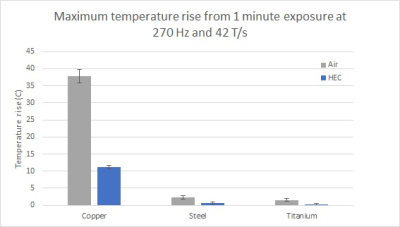

As expected, annuli exposed to a gradient field

in air cause a significantly higher temperature rise than measurements

conducted in HEC gel (Figure 2). From the three metals tested, copper had a

significantly higher temperature rise compared to steel and titanium annuli. Exposing

a copper annulus to changing dB/dt resulted in a temperature rise (ΔT) consistent

with the equation: ΔT = 5.8E-3*(dB/dt)2 (Figure 3A) and

changing frequency (f) resulted in decreasing temperature rise consistent with: ΔT

= 1.6E4*f-1.3 (Figure 3B). A 10.7 ± 0.2 °C temperature rise was

measured for the copper annulus from 11 repeats.

Discussion

Devices may be tested in gel or in air, depending on the application and therefore the response of the standard object must be characterized in both. Heat conduction from the disk to the HEC gel throughout the exposure decreases the temperature rise but results in more repeatable measurements, presumably due to a more consistent heat transfer mechanism (as compared to exchange with air). Of the metals tested and as expected, copper resulted in the largest eddy current induced temperature rise. The decreased temperature rise from increasing frequency was consistent with previous work by Harris et al.3 The use of a relatively thick annulus allows for holes on either end to be drilled halfway through the metal for increased repeatability of temperature probe placement (as is done with the standard Ti-rod for RF heating). Although the proposed standard objects were tested in lab-based dB/dt exposure systems, the use of these objects for characterizing and monitoring exposures within MRI scanners is expected to be equally valid.Conclusion

A 50-mm OD, 30-mm ID, 3-mm thick copper annulus is proposed for use as a standard reference object for the purposes of characterizing and monitoring dB/dt exposure tests, in either air or tissue-mimicking materials, as described in applicable test standards.Acknowledgements

The authors would like to acknowledge the funding received from the NSERC Industrial Research Chairs Program, Ontario Research Fund Research Excellence Program, and Canadian Foundation for Innovation.References

1. ASTM F2182: Test Method for Measurement of Radio Frequency Induced Heating On or Near Passive Implants During Magnetic Resonance Imaging. Pennsylvania, USA: ASTM International; 2011.

2. ISO, DTS 10974 (2nd Ed): Assessment of the safety of magnetic resonance imaging for patients with an active implantable medical device. Geneva, Switzerland: International Organization for Standardization; 2016.

3. Harris, C. T., et al. "Application and experimental validation of an integral method for simulation of gradient-induced eddy currents on conducting surfaces during magnetic resonance imaging." Physics in medicine and biology 58.12 (2013): 4367.

Figures