3450

A dedicated MRI flow laboratory for quantitative flow measurements and method development1Institute of Fluid Mechanics, University of Rostock, Rostock, Germany

Synopsis

A unique MRI flow laboratory is currently being commissioned at the University of Rostock. The laboratory is specifically designed for quantitative measurements in technical flows. The MRI system, a whole-body Magnetom Trio (Siemens, Erlangen, Germany), will be integrated into various flow circuits with water and other fluids. This MRI system is not intended for clinical trials. Instead, the research focuses on the development and validation of flow quantification methods for medical and technical applications. The long-term aim is to make MRI more available to the field of fluid mechanics research and flow engineering.

INTRODUCTION

A unique MRI flow laboratory is currently being commissioned at the University of Rostock. The laboratory is specifically designed for quantitative measurements in technical flows. The MRI system, a whole-body Magnetom Trio (Siemens, Erlangen, Germany), will be integrated into various flow circuits with water and other fluids. This MRI system is not intended for clinical trials. Instead, the research focuses on the development and validation of flow quantification methods for medical and technical applications.

In addition to method development and validation experiments, the unique setup of the laboratory offers various other fields of research. The MRI system will be used as tool to study and design industrial flow systems. Scaled models of flow systems such as fluid circuits in engines, but also models of medical implants such as stents and ventricular assist devices can be quickly measured in this facility.

The presentation at the meeting will discuss the conception, planning, implementation and commissioning of this laboratory as well as future research opportunities.

METHODS

The MRI flow laboratory was designed in close cooperation with Siemens Healthcare (Erlangen, Germany). The main objective was to provide a highly specialized laboratory for quantitative measurements in flow models. Particular attention was paid to the flexibility and upgradability of the laboratory for future flow experiments as well as operational safety.

RESULTS

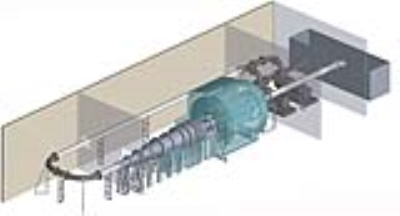

The completed MRI flow laboratory consists of a 104 square meter freestanding one-story building divided into four rooms, each designed for a specific function, as explained in Fig. 1. The examination room with the MRI system is equipped with a sealed floor and a drainage system to account for possible leakage during experiments with water circuits. Furthermore, all walls in the examination room are equipped with mounting rails for quick and easy installations of pipes and other flow circuit elements. Six waveguide panels in the walls of the examination room can be used to connect the flow circuit to other rooms. Another remarkable feature is a ceiling rail system above the MRI system to support heavy flow models up to 700 kg. The flow supply room has an increased floor load-bearing capacity of 1200 kg per square meter to accommodate large water tanks and heavy pump systems. Additional flow equipment such as heaters and coolers or smaller pump systems can be placed inside the control room. Both the control room and the flow supply room are equipped with heavy-power sockets and two-meter wide doors to ensure unrestricted compatibility with heavy-duty flow equipment.

Another distinct feature is the overall arrangement of the laboratory. As shown in Fig. 1, the axis of the MRI system is aligned with two waveguide panels in the walls of the examination room as well as with the windows in the building walls. With this alignment, it is possible to place a straight pipe through the building and through the MRI system. Outside the building the piping can be extended to more than 40 meters in both directions. Such long experimental setups will be used in high-accuracy flow experiments in which fully-developed flow conditions must be provided.

An example of a future installation is depicted in Fig. 2. In this setup, a water circuit capable of a volumetric flow rate of up to 10.000 liters per minutes combined with a 300 mm diameter test section will be used to achieve fully-turbulent flow conditions at a Reynolds number of up to 800.000.

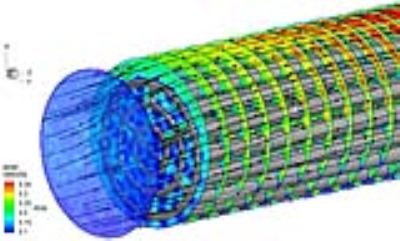

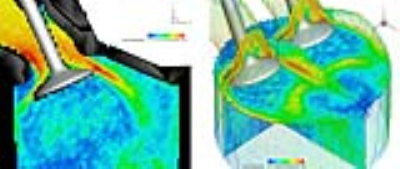

Two sample measurements, which were carried out in precursory studies on a clinical MRI system are depicted in Fig. 3 and Fig.4. The images show the velocity results in a model of a nuclear fuel bundle1 and a model of an internal combustion engine2. Similar setups will be investigated in the new laboratory but under more controlled and more realistic flow conditions than in these precursory studies.

DISCUSSION & CONCLUSION

The new MRI laboratory at the University of Rostock provides a completely new field of application for MRI-based flow quantification. The unique integration of a whole-body MRI system in a dedicated flow laboratory provides unprecedented possibilities for fluid mechanics research and flow engineering.Acknowledgements

No acknowledgement found.References

- 1. Bruschewski M, Freudenhammer D, Piro MHA, Tropea C and Grundmann S. New insights into the flow inside CANDU fuel bundles using magnetic resonance velocimetry. Proc. Comp. Fluid Dyn. Nucl. React. Safety 2014, Cambridge, USA

- 2. Freudenhammer D, Baum E, Peterson B, Böhm B, Jung B, Grundmann S. Volumetric intake flow measurements of an IC engine using magnetic resonance velocimetry. Exp Fluids 2014;55(5):1724

Figures