Ryusuke Nakai1,2, Takashi Azuma3, Mitsuaki Toda2, Tomonobu Kodata4, and Hiroo Iwata2

1Kokoro Research Center, Kyoto University, Kyoto, Japan, 2Institute for Frontier and Medical Life Sciences, Kyoto University, Kyoto, Japan, 3Graduate School of Engineering, Kyoto University, Kyoto, Japan, 4Department of Neurosurgery, Jikei University School of Medicine, Tokyo, Japan

Synopsis

Relatively less invasive

MRI has recently been increasingly used for examination after coil embolization

of a cerebral aneurysm, but there is a risk of misdiagnosis due to magnetic

susceptibility artifacts. In this study, we developed a device composed of a

highly biocompatible alloy with magnetic susceptibility equivalent to that of mammalian

tissue, and evaluated it using both an in vitro model and rabbits. We found that

this alloy markedly reduced magnetic susceptibility artifacts and can be used

as a device in the body. We are planning to develop various implantable medical

devices using this alloy.

Purpose

Coil embolization of cerebral

aneurysms has recently been performed as a standard treatment. Periodic postoperative

examination is essential after this surgery, and relatively less invasive MRI

has recently been increasingly used for postoperative examination. However, new

problems have been discovered with increased use of MRI. Magnetic

susceptibility artifacts produced by conventional metal coils have a marked

influence on the MRI findings that determine the treatment strategy, and a risk

of misdiagnosis due to artifacts has been observed. Focusing on a diamagnetic

metal, Au, and a paramagnetic metal, Pt, with consideration for both biocompatibility

and mechanical characteristics, we investigated the composition and processing

method of an alloy prepared with these metals. Our aim was to develop an alloy

for coil treatment of cerebral aneurysm embolization with magnetic susceptibility

equivalent to that of the human tissues and thus not produce magnetic

susceptibility artifacts.Materials and Methods

Alloys

were prepared as follows: Metal pellets were placed in a zirconia crucible,

heated, melted by high frequency induction heating, and casted employing tilting

casting. The ingots were treated with hot forming to destroy solidified material.

In addition, groove rolling was applied followed by heat treatment at 1100℃ in the

atmosphere for one hour or longer. Groove rolling and heat treatment were

performed two more times. Several samples with different compositions were

prepared using this process with a single-phase treatment. In

an artifact evaluation experiment, column-shaped (diameter 3 mm and length 8 mm) alloy samples were fixed with

agarose gel in a test tube and tested (Figure 1). These experimental samples and samples

prepared with the conventional PtW alloy were subjected to magnetic

susceptibility measurements using SQUID

Quantum Design MPMS-7 (7T-SQUID

Fluxmeter, Quantum Design Japan, Tokyo, Japan) and MRI using a 1.5-T scanner (MAGNETOM Sonata, Siemens A.G., Erlangen,

Germany). We

developed a coil with a small-bore diameter for high-resolution for the coil

receiving signals. MR images were acquired following the criteria of both the spin echo (TR:500ms, TE:20ms, pixel size:0.5×0.5mm, thickness:2mm, NEX:2) and gradient echo (TR:250 ms, TE:15 ms, pixel size:0.4×0.4mm, flip angle:30deg., thickness:2mm, NEX:2) sequence required by the US FDA standard artifact

evaluation test1. The artifact length from the sample margin was measured in the

acquired images using artifact measurement software prepared by us. A coil prepared with the metal composition

producing the smallest artifact and the conventional coil prepared with PtW

were placed in a rabbit aneurysm model, and MRI images were acquired employing

the 3D-TOF (TR:41ms, TE:9.21ms, pixel size:0.19×0.19mm, flip angle:25deg., thickness:0.8mm) sequence. The sizes of the artifacts in the images were compared.Results and Discussion

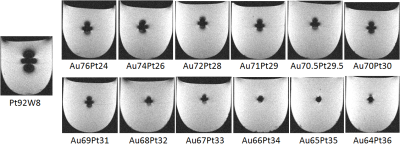

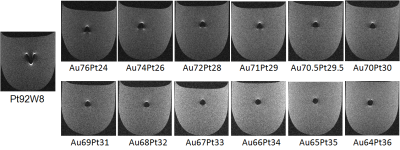

In the in vitro experiment,

the artifact produced by the newly developed alloy was smaller than that

produced by the conventional alloy in images acquired by both the spin echo (Figure 2) and gradient echo sequence (Figure 3). The artifact length was correlated with the measured

magnetic susceptibility of the alloy, and the artifact size decreased as the

susceptibility became close to that of the surrounding tissue. Development of

an alloy producing a negligible artifact was achieved. In addition, using a

coil for aneurysm embolization prepared with this alloy material, magnetic

susceptibility artifacts produced by the aneurysm in the body could be markedly

reduced. Since small changes in the alloy preparation process may influence the

magnetic susceptibility, strict control of the preparation process is important.Conclusion

By adjusting the

composition of the embolization coil in consideration of the alloy preparation

method, an alloy with magnetic susceptibility equivalent to that of human

tissue could be prepared that markedly reduced magnetic susceptibility artifacts.

Development of MRI-compatible implantable devices for the body will be a priority.Acknowledgements

No acknowledgement found.

References

1. ASTM F2119, Annual Book of ASTM Standards, Vol. 13.01.