4435

Low-attenuation RF surface coils for linac-MR hybrids: compromise between radiation dose to the skin and SNR1Oncology, University of Alberta, Edmonton, AB, Canada, 2Medical Physics, Cross Cancer Institute, Edmonton, AB, Canada

Synopsis

Aluminum and copper conductors are compared for constructing radiologically transparent MRI surface coil detectors for use in a hybrid MRI - linear accelerator. Radiation dose to skin can cause serious reactions and skin dose is enhanced when materials are placed in the radiation beam. Therefore increases in skin dose due to surface coils must be minimized by optimized construction. A copper conductor causes a three-fold increase in skin dose compared to a similar thickness aluminum conductor. An aluminium coil (20μm thick) was used to image a phantom, yielding 93% of the SNR achieved with a copper tape coil (32μm thick).

Purpose

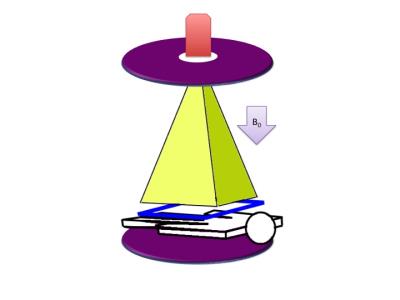

The linac-mr combines the treatment capabilities of a linear accelerator (linac) and the imaging capabilities of MRI, making real-time image-guided adaptive radiotherapy possible (see Figure 1)1 . However, radiation dose to the skin is enhanced by materials (especially high-density metals like copper) placed in the radiation beam’s path2, which can cause serious reactions3. Therefore, to take advantage of the high signal-to-noise ratio (SNR) provided by surface coils and arrays4, an optimized design is required to minimize increases in skin dose, while sacrificing as little SNR as possible. Aluminum has been investigated for low-attenuation of kV photons by coils used in an x-ray/MR system5, but the skin dose effects due to high-energy (MV) radiation have not been investigated for aluminum coils.

In this work we compare the performance of aluminum and copper coils in terms of skin dose and image quality.

Methods

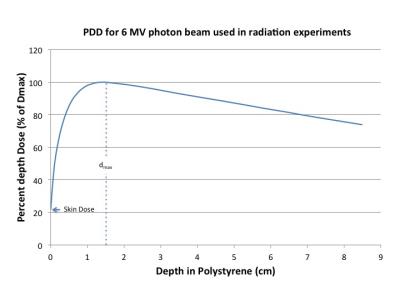

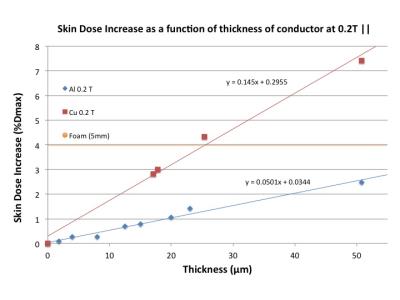

A 6MV beam linac and a parallel plate ion chamber were used to measure increases in surface dose due to sheets of aluminum, copper, and insulating Styrofoam (5 mm thick) relative to the open beam. The dose under a patient gown was also measured as a reference for skin dose increase. A 0.2 T magnetic field was generated with a double donut magnet to simulate the electron trapping effect of the MRI system’s field. The skin dose is given as a percentage of the maximum dose (Dmax, which occurs at a depth of dmax – see Figure 2).

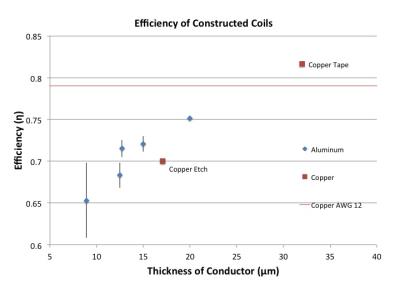

To characterize the impact of conductor thickness and material on SNR, coils were constructed from aluminum foils (8. 9, 12.5, 12.7, 15 and 20 μm thickness), copper tape (32μm), flexible PCB (17μm), and copper wire (2.05mm diameter). The coils were all 15 × 15 cm2 square loops of 6 mm-wide strip conductors with 12 cm connections to a matching network.

Each coil was tuned to 20.56 MHz (f0) and matched to 50Ω. Loaded and unloaded quality factor (Q) were determined with a VNA S21 measurement using a small probe. Efficiency was calculated6:

$$\eta = 1- \frac{Q_{L}}{Q_{U}}$$

The efficiency predicts how much of the intrinsic SNR can be achieved with the coil6:

$$SNR=\sqrt{\eta}*iSNR$$

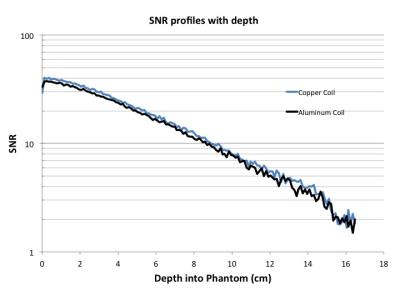

A thickness of aluminum was selected that increases skin dose less than a gown pocket while preserving as much SNR as possible. This aluminum coil and a standard copper coil were tested on a phantom in a 0.5 T linac-mr system7. Single slice (20mm thick) images were acquired with a spin-echo (20ms TE) T1-weighted sequence (416ms TR) to measure SNR.

Results

Skin dose increases due to aluminum and copper of various thicknesses are summarized in Figure 3. The skin dose increase due to 5 mm of Styrofoam was 4% (horizontal line in Figure 3). Skin dose increase due to a gown is 6.1% while the gown pocket (double layer) increases dose by 11.3% (i.e., approximately additive effects). The efficiencies of the coils are shown in Figure 4. The highest achieved efficiency was 0.82 with copper tape and with aluminum it ranged from 0.65 (8.89μm) to 0.75 (20μm). Since 20 μm increases the skin dose by only 1%, this thickness was therefore chosen for the SNR measurement (Figure 5). On average the SNR for the aluminum coil was 7% lower than that of the copper tape coil.Discussion

As expected, thicker metal foil causes a greater skin dose increase because there is more material for radiation to interact with. Furthermore, copper interacts more with the beam than aluminum because of its higher density and atomic number.

Thicker copper conductors have increased SNR efficiency because of lower resistance than thin aluminum. Nevertheless, an approximately 17-μm-thick aluminum coil will achieve 90% of the SNR of the copper tape coil. Keeping in mind that foam insulation required for RF safety increases dose by 4%, to have the same impact as a gown pocket (5.2% skin dose increase) the maximum conductor thicknesses are 21.0 μm of aluminum or 7.2 μm copper (1.2% skin dose increase). A 7.2 μm copper coil will provide far poorer SNR than 21 μm aluminum.

The aluminum coil (20μm thick) achieved 93% of the SNR of the copper coil (32μm thick), slightly lower than the predicted 96%. This may be due to limitations in coil construction, set-up uncertainty, and variations in scan calibrations.

Conclusion

Allowable conductor thickness is limited by skin dose for surface coils that must be radiologically transparent. Using aluminum rather than copper greatly reduces unwanted skin dose increase and with 20 μm aluminum the SNR is 93% of that of the copper tape coil used for reference.Acknowledgements

We would like to thank Alberta Innovates Health Solutions (AIHS), Alberta Cancer Foundation (ACF), Natural Sciences and Engineering Research Council (Canada), Canadian Institutes of Health Research (CIHR), and the University of Alberta for funding. We would also like to thank Alberta Health Services (AHS) for providing the facilities and support for the linac-mr project.References

1) J. Yun, K. Wachowicz, M. Mackenzie, S. Rathee, D. Robinson, and B. G. Fallone, “First demonstration of intrafractional tumor-tracked irradiation using 2D phantom MR images on a prototype linac-MR.,” Med. Phys., vol. 40, no. 5, p. 51718, May 2013.

2) A. Ghila, B. G. Fallone, and S. Rathee, “Influence of standard RF coil materials on surface and buildup dose from a 6 MV photon beam in magnetic field,” Med. Phys., vol. 43, no. 11, 2016.

3) A. J. Olch, L. Gerig, H. Li, I. Mihaylov, and A. Morgan, “Dosimetric effects caused by couch tops and immobilization devices: Report of AAPM Task Group 176,” Med. Phys., vol. 41, no. 6, 2014.

4) S. M. Wright, “Receiver Loop Arrays,” in RF coils for MRI, J. T. Vaughan and J. R. Griffiths, Eds. West Sussex, United Kingdom: John Wiley & Sons Ltd, 2012, pp. 65–80.

5) V. Rieke, A. Ganguly, B. L. Daniel, G. Scott, J. M. Pauly, R. Fahrig, N. J. Pelc, and K. Butts, “X-ray compatible radiofrequency coil for magnetic resonance imaging,” Magn. Reson. Med., vol. 53, no. 6, pp. 1409–1414, 2005.

6) W. A. Edelstein, G. H. Glover, C. J. Hardy, and R. W. Redington, “The intrinsic signal-to-noise ratio in NMR imaging.,” Magn. Reson. Med., vol. 3, no. 4, pp. 604–618, Aug. 1986.

7) A. Keyvanloo, B. Burke, J. St Aubin, D. Baillie, K. Wachowicz, B. Warkentin, S. Steciw, and B. G. Fallone, “Minimal skin dose increase in longitudinal rotating biplanar linac-MR systems: examination of radiation energy and flattening filter design.,” Phys. Med. Biol., vol. 61, no. 9, pp. 3527–3539, May 2016.

Figures

Figure 3: This figure shows the skin dose increase when different thicknesses of copper and aluminum are placed in the radiation beam, including the effect of a 0.2 T magnetic field parallel to the beam. The different slopes of the linear fits highlight the reduction in skin dose achievable with aluminum instead of copper, i.e., the skin dose increases 2.9 times more with copper than with the same thickness of aluminum.