2685

A scalable, MR compatible temperature measurement and control system1Institute for Biomedical Engineering, University and ETH Zurich, Zurich, Switzerland, 2University and ETH Zurich, Zurich, Switzerland

Synopsis

Tight temperature control of various devices is required to guarantee highly stable experimental conditions. E.g. B0 field shifts induced by heating of shim irons or gain changes induced in preamplifiers can be avoided by oven controlling the critical components of the device. Furthermore, a recently presented approach of active shimming with controlled magnetic materials requires tight temperature control of a large count of devices in parallel in the bore. For such applications, we present a 14 channel, low power, MR compatible temperature measurement and control system which can be parallelized for a scalable channel count.

Purpose

Temperature

drifts are a major source of measurement instabilities in RF devices, coils, magnets

and passive shimming units and are typically hard to calibrate. Therefore, tight

temperature control of various devices is often required for achieving a high

degree of reproducibility. Such oven controlling could suppress B0 field drifts

induced by heating up shim irons as well as temperature induced signal alterations

in RF chains and coils. Additionally, a recently demonstrated approach for

local shimming using temperature controlled magnetic materials [1] requires

tight temperature control of a large count of particles. In order to keep the

cable count and the interferences low, the control system has to be located in

the bore.

Therefore a

high channel count, MR compatible modular thermostat system is required. In

particular, when temperature controlled components, such as the mentioned magnetic

materials, have to be integrated into local coil arrays the thermostat is

required to have a small form factor, low weight, low power consumption and must

connect via a low count of cables.

In this

work we present a modular, parallelizable, MR compatible, miniature thermostat

system with scalable channel count comprising means for high fidelity reading of

temperature sensors, power efficient control of heating currents and a

digitally programmable control loop.Methods

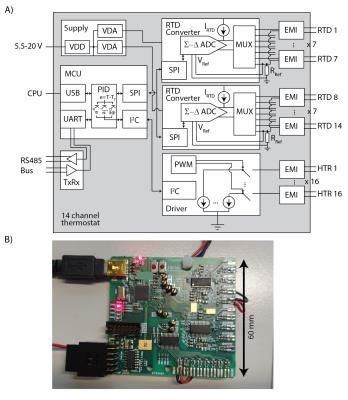

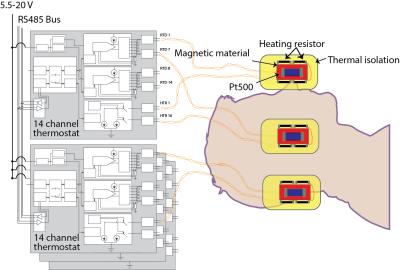

The system

is composed of small (62x60 mm) PCBs (Fig.1) that can be controlled fully in

parallel via a single supply line and a RS485 bus requiring only minimum wiring

connections (Fig.2). Each board offers 24-bit readings of 14 thermocouples

(RTD), a 4 MHz controller for flexible implementation of the actual control

loop function and 8-bit pulse-width-modulation (PWM) control of the heating

power of 16 heaters in parallel with maximally 2.4W each. Each board hosts

supply voltage regulation for all components offering a high grade of interference

rejection on the supply line as required for in-bore operation. Each board has

isolated line drivers for the communication bus and an USB2.0 connection for

debugging purposes.

The reading

of the temperature sensors [2] is implemented using two 24-bit sigma-delta

converter with integrated precision current sources (ADS1248, TI, Dallas, TX,

USA). The 7 thermocouples attached to one ADC unit are sequentially connected

via the integrated switches and have individual filters for blocking RF interferences.

Both converters can be configured and operated fully in parallel. The

resistance of the RTD is measured in a ratiometric fashion in order to suppress

externally induced voltages.

The control

of the heating current is implemented using a 16-channel LED low side PWM

driver (TLC59116, TI, Dallas, TX, USA). The device integrates the generation of

the modulation frequency, the constant current sources and the switches in a

minimal form factor reducing emission of electromagnetic interferences. The outputs

of the controller are filtered.

The control

loop is a remotely parameterizable proportional-integral-differential

controller (PID) with integral term clamping implemented on an 8-bit

microcontroller (MCU, ATmega32U4, Atmel, San Jose, CA, USA). The peripheral

devices are connected via different bus systems in order to provide largely

parallel data transfers.Results

The noise

of the RTD reader using a Pt500 thermistor (IRTD=1mA) was

0.0034°K/√Hz. The loop roundtrip time for 1 channel was below 15ms, for 14 below

60ms.

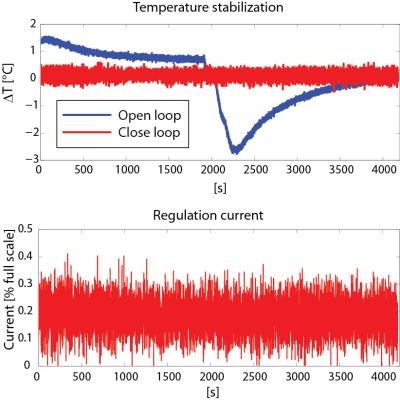

Fig.3 shows

an example of regulating the temperature of a device that is briefly exposed to

an airstream as present in the bore in comparison to the unregulated case. It is seen that temperature drifts are majorly suppressed.

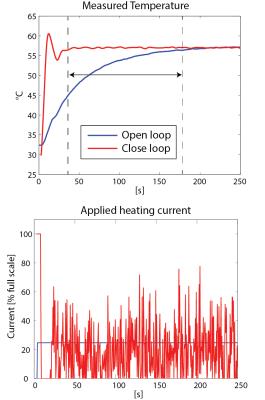

Fig.4

compares levelling of a shim unit from room temperature to 57°C with and

without feedback loop exhibiting a speed advantage of more than 4 times using

active regulation. The applied heating current shows that the regulator makes

use of the full power in order to achieve a fast temperature rise initially.Conclusion

Precision

measurements and control of the temperature of small components is realized MRI

compatibly even for large channel counts regarding form factor, cabling, power

consumption and its magnetic moment.

Accurate

temperature measurements give valuable information on system components in

bore. Furthermore, thigh control of shim irons can either be used for

stabilizing the main magnetic field or for adaptive control for shimming

purposes.

Active

temperature control effectively stabilizes the temperature of a device and

provides a several times faster settling. The latter is required in particular

for adjusting shim settings using controllable magnetic materials [1] in order

to keep preparation times low. In conjunction with the small form factor, the

power efficient design and the low count of required cabling these systems can be

directly employed for control of such on-coil shimming units. Acknowledgements

No acknowledgement found.References

[1] Brunner DO et al. Magnetic Pebbles – Materials with Controllable Magnetism for Compact, Low-Power Shim Units, Proc ISMRM 2016, Singapore, p.0492

[2] Haefner J et al, Development of a cost-effective and MRI compatible temperature measurement system, Biomed Tech 47 Suppl 1 Pt 2 , 2002, p. 664-667

Figures